3D Printing in Pump Manufacturing?

3D Printing in Pump Manufacturing?

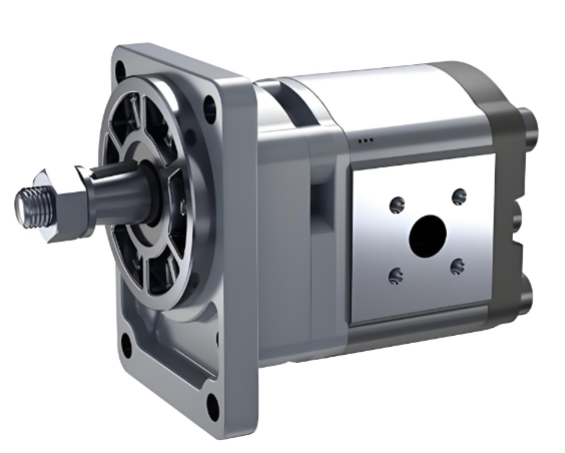

Printing Complex Parts for Peak Performance

The most immediate impact of 3D printing, or Additive Manufacturing, is the freedom to create components with complex geometries that are impossible to achieve with traditional casting or machining. The heart of a pump—the impeller—is a perfect example. Traditional impellers have simple, curved vanes due to manufacturing constraints. However, with 3D printing, Gaotian engineers can design and produce impellers with sophisticated, bio-mimetic internal channels and optimized vane shapes. This results in a lightweight design that reduces inertia and a significant boost in hydraulic efficiency. Water flows more smoothly with less turbulence and cavitation, directly translating to higher performance and lower energy consumption. This is not a future concept; it's a present-day reality in Gaotian's advanced manufacturing workflow.

Accelerating Innovation and Unlocking Unprecedented Customization

The product development cycle is dramatically accelerated with rapid prototyping. What once took weeks for a foundry to produce a single prototype can now be printed in-house by Gaotian in a matter of days. This speed enables rapid design iteration, allowing engineers to test, refine, and optimize components at an unprecedented pace. Furthermore, 3D printing unlocks the potential for custom pump solutions that were previously economically unviable. For unique industrial applications requiring specific flow characteristics or materials, Gaotian can now practice on-demand manufacturing of specialized parts without the need for expensive and time-consuming tooling. This shift from mass production to mass customization allows Gaotian to solve niche challenges with tailor-made precision, offering clients a level of specificity that sets them apart in their respective fields.

Strengthening the Supply Chain

Perhaps the most transformative long-term impact lies in supply chain management. Instead of maintaining a vast physical inventory of spare parts for countless pump models, Gaotian can move towards a digital inventory. They can store digital design files securely in the cloud. When a client needs a specific, perhaps obsolete, part, Gaotian can simply print it locally or at a regional service center, enabling true spare parts on-demand. This approach dramatically enhances supply chain resilience, reducing dependency on long-distance shipping and minimizing downtime for clients. It represents the pinnacle of advanced manufacturing, where digital files replace physical stockpiles, ensuring that critical support is always just a print away.

3D printing is far more than a niche tool for Gaotian; it is a strategic capability integrated into their core research, development, and service operations. By leveraging this technology, they are not only creating superior, more efficient pump components but also building a more agile, responsive, and customer-centric business model. This commitment to advanced manufacturing ensures that Gaotian remains at the forefront of the industry, delivering innovative solutions that directly address the evolving needs of their clients.