A Comparison of Lobe Pumps, Gear Pumps, and Screw Pumps

A Comparison of Lobe Pumps, Gear Pumps, and Screw Pumps

Gentle Handling and Hygienic Performance of Lobe Pumps

Lobe pumps, a type of positive displacement pump, are distinguished by their exceptional ability to handle sensitive, viscous, and solid-laden fluids with minimal shear or damage. They operate using two or more lobes that rotate synchronously within the pump casing, moving fluid from the suction to the discharge side without metal-to-metal contact between the lobes. This gentle pumping action is ideal for products like fruit pieces in juices, yogurt, creams, and slurries where maintaining product integrity is paramount. Furthermore, their design allows for easy cleaning and sterilization, making them the preferred choice in the food and beverage, pharmaceutical, and cosmetic industries where strict hygienic (sanitary) standards are required. While they offer excellent versatility, lobe pumps can have a higher initial cost compared to some alternatives and may require more complex sealing arrangements. For applications demanding hygiene and gentle product handling, lobe pumps from manufacturers like GAOTIAN provide an optimal solution.

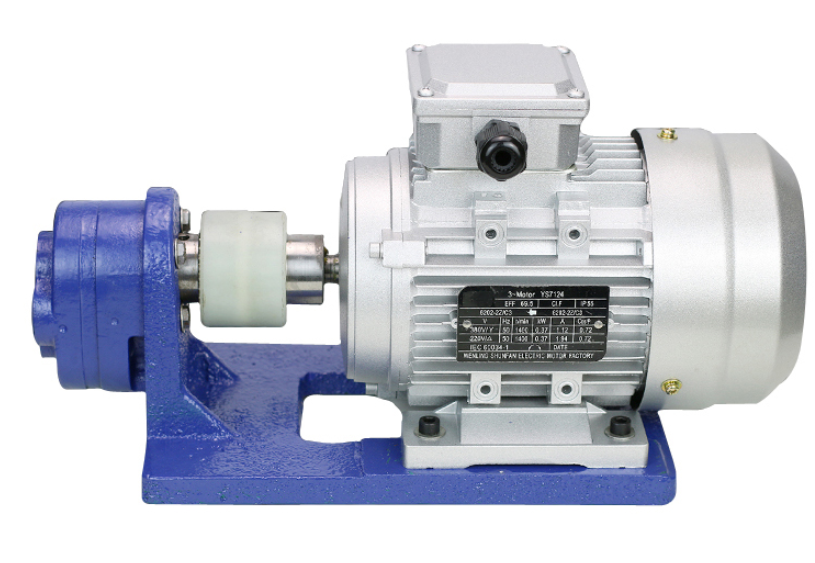

Compact Efficiency and Cost-Effectiveness of Gear Pumps

Gear pumps are renowned for their simplicity, compact size, and high efficiency in handling viscous fluids. They function through the meshing and rotation of two gears (one driven, one idler) within a tight-clearance housing. As the gears unmesh at the suction inlet, they create a void that draws in fluid; this fluid is then carried within the spaces between the gear teeth and the housing to the discharge side, where the meshing gears force it out. This design results in a continuous, pulseless flow. Gear pumps are highly efficient for oils, fuels, paints, and adhesives, and they are often the most cost-effective option for medium-pressure applications. However, they are generally not suitable for fluids with abrasives, as the close tolerances can lead to rapid wear, and the pumping action can impart higher shear, which may damage shear-sensitive materials. For reliable transfer of lubricating fluids in industrial settings, GAOTIAN's gear pumps offer a robust and economical choice.

High-Pressure Capability and Low-Pulsation Flow of Screw Pumps

Screw pumps, specifically progressing cavity pumps, excel in handling very high viscosity fluids, achieving high pressures, and delivering an extremely smooth, low-pulsation flow. Their operation is based on a single helical rotor turning within a double-threaded helical stator, creating a series of sealed cavities that progress continuously from the suction to the discharge end. This design makes them exceptionally effective for pumping challenging fluids like heavy fuels, grease, sludge, wastewater, and pastes without causing agitation or aeration. Screw pumps are workhorses in industries such as oil and gas, wastewater treatment, and marine applications, where consistent flow under high pressure is critical. The main considerations for screw pumps are that they can be sensitive to dry running and the stator, typically made of an elastomer, may have limitations with certain chemicals or temperatures. For demanding high-pressure transfer of viscous and abrasive media, GAOTIAN's screw pumps provide reliable and consistent performance.

In summary, the choice between lobe, gear, and screw pumps is dictated by the specific application requirements. Lobe pumps are ideal for sanitary, gentle handling; gear pumps offer compact efficiency for lubricating fluids; and screw pumps provide high-pressure, low-shear flow for viscous media. GAOTIAN's expertise across these pump types ensures that customers can select the most efficient and reliable technology for their unique process needs.