A Technical Overview of Gaotian's High-Pressure Multistage Booster Pumps

A Technical Overview of Gaotian's High-Pressure Multistage Booster Pumps

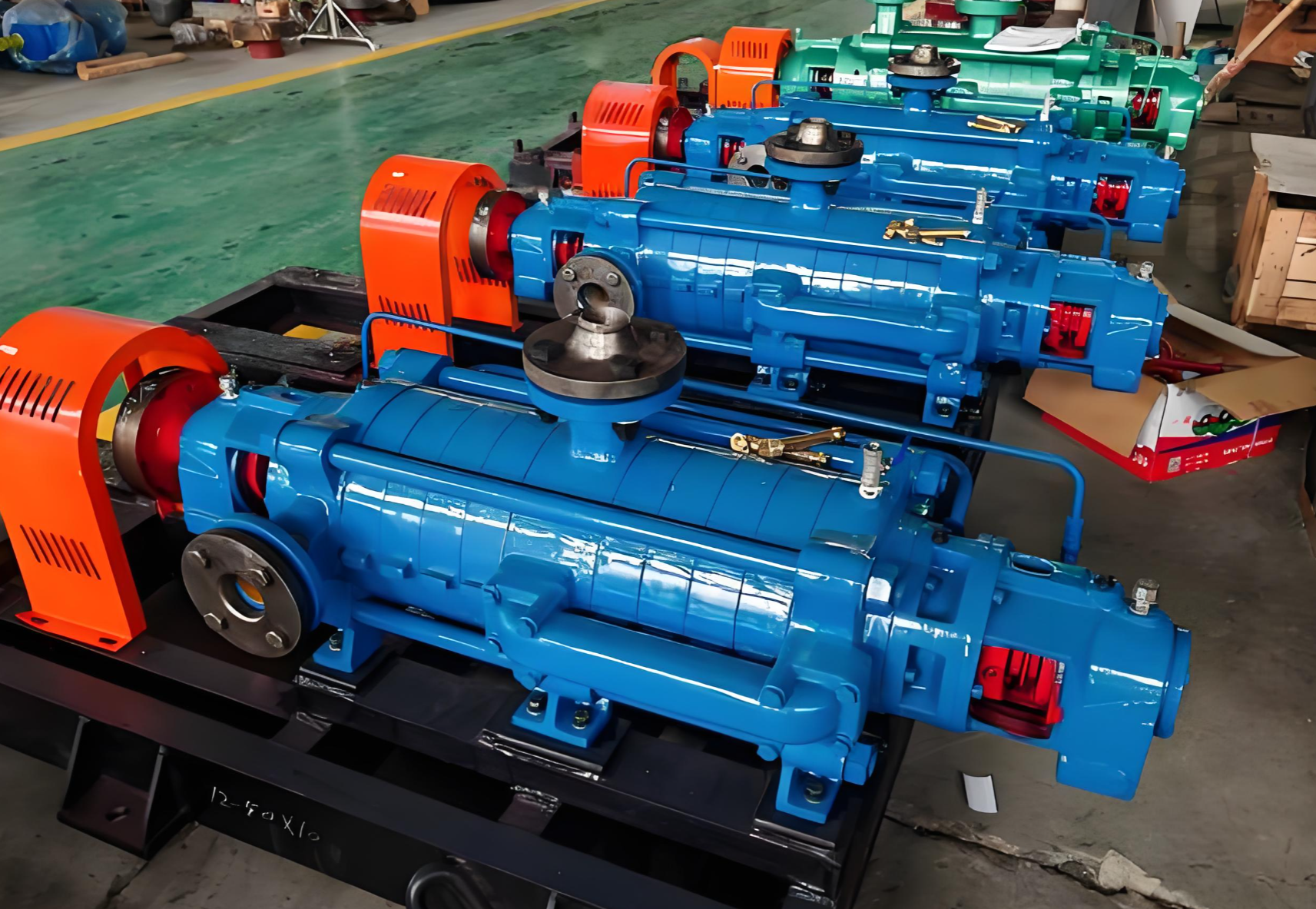

In applications where consistent, high-pressure water supply is non-negotiable—such as in high-rise buildings, industrial cleaning, reverse osmosis (RO) systems, and boiler feed—standard single-stage centrifugal pumps often fall short. Shanghai Gaotian Pump Manufacturing Co., Ltd. meets this critical demand with its engineered range of high-pressure multistage booster pumps. These pumps are designed on the fundamental principle of staging, where multiple impellers and diffusers are arranged in series within a single pump casing. This ingenious design allows each stage to incrementally increase the fluid pressure, resulting in a cumulative discharge pressure that far exceeds what a single impeller can achieve. Gaotian's multistage design provides a compact, efficient, and highly reliable solution for generating the substantial pressures required to overcome system losses and deliver water to great heights or through demanding industrial processes.

Core Engineering and Design: Precision, Materials, and Performance

The exceptional performance of Gaotian's multistage pumps is rooted in precision engineering and high-quality materials. The heart of the pump consists of individually cast or stamped stainless steel impellers, known for their strength, corrosion resistance, and hydraulic efficiency. Each impeller is precisely matched with a stationary diffuser, which efficiently converts the velocity energy imparted by the impeller into stable pressure energy while guiding the flow to the next stage. A critical technical challenge in multistage pumps is managing the immense axial thrust generated by the stacked impellers. Gaotian addresses this through advanced hydraulic balancing systems, such as a balancing drum or balancing discs, which counteract this force, minimizing wear on bearings and ensuring smooth, vibration-free operation and extended service life. The entire assembly is driven by a high-efficiency electric motor, often coupled with a Variable Frequency Drive (VFD) option, allowing for precise pressure control and significant energy savings by matching pump output to real-time demand.

Versatile Applications Across Critical Industries

The design versatility of Gaotian's high-pressure multistage pumps makes them indispensable across a wide spectrum of industries. In water treatment, they serve as high-pressure booster pumps for Reverse Osmosis (RO) systems, providing the necessary force to push water through semi-permeable membranes for purification and desalination. For municipal and commercial buildings, they are the core of pressurized water supply systems, ensuring consistent water pressure on upper floors of skyscrapers, hotels, and hospitals. In industrial settings, these pumps are crucial for high-pressure cleaning processes, supplying water for hydraulic descaling, and acting as reliable boiler feed pumps in power plants and manufacturing facilities. Their ability to generate clean, pulsation-free high pressure also makes them suitable for applications in car washes, aquaculture, and irrigation systems for large-scale agricultural projects. Gaotian offers various materials of construction, including standard cast iron and full stainless steel, to handle everything from clean water to mildly corrosive fluids, ensuring application-specific reliability.

In summary, Gaotian's high-pressure multistage booster pumps represent a pinnacle of centrifugal pump engineering, offering a sophisticated and efficient solution for generating high pressure in a compact footprint. Through their staged impeller design, precision-balanced hydraulics, and robust construction, they deliver unmatched reliability and performance for the most demanding pressure-boosting applications. By selecting a Gaotian multistage pump, industries and municipalities invest not only in a piece of equipment but in the guaranteed consistency of their critical water and process fluid systems, ensuring operational continuity, energy efficiency, and long-term value.