Gear Pumps for High-Viscosity Liquids

Gear Pumps for High-Viscosity Liquids

The Working Principle: Positive Displacement and Consistent Flow

Gear pumps excel in handling high-viscosity liquids primarily due to their positive displacement operating principle. Unlike centrifugal pumps whose efficiency plummets as fluid thickness increases, gear pumps feature two meshing gears—a driven gear and an idler—rotating within a tightly toleranced housing. As the gears unmesh at the pump inlet, they create an expanding volume that draws viscous liquid into the cavities between the gear teeth. This trapped fluid is then carried around the periphery of the pump housing to the discharge side. There, the re-meshing of the gears forces the liquid out through the outlet port, providing a highly consistent, non-pulsating flow. This mechanical action is inherently effective with thick fluids like oils, syrups, resins, and paints because it relies on physically displacing a fixed volume of fluid with each revolution, rather than imparting kinetic energy. The result is a steady, measurable output directly proportional to the pump's speed, which is crucial for precision applications such as metering, blending, and dispensing where flow accuracy is paramount, regardless of changes in pressure or fluid consistency.

Advantages Over Other Pump Types in High-Viscosity Applications

When dealing with high-viscosity liquids, gear pumps present distinct advantages that make them superior to centrifugal and even other positive displacement pumps in many scenarios. Their most significant benefit is high volumetric efficiency; they maintain a consistent flow rate even against significant system backpressure, ensuring reliable performance in processes requiring precise throughput. Secondly, gear pumps possess excellent self-priming capabilities. Their ability to create a strong vacuum at the inlet allows them to effectively lift viscous fluids from tanks or drums without the need for external priming devices. Furthermore, their design is remarkably simple and robust, with fewer moving parts compared to complex piston pumps, leading to lower maintenance requirements, easier servicing, and greater reliability when handling abrasive slurries or filled materials. Gear pumps also operate effectively at low speeds, which is ideal for shear-sensitive liquids like polymer melts or certain food products, as it minimizes degradation or alteration of the fluid's properties. This combination of reliability, simplicity, and performance solidifies their role as the workhorse pump for demanding high-viscosity transfer and circulation tasks.

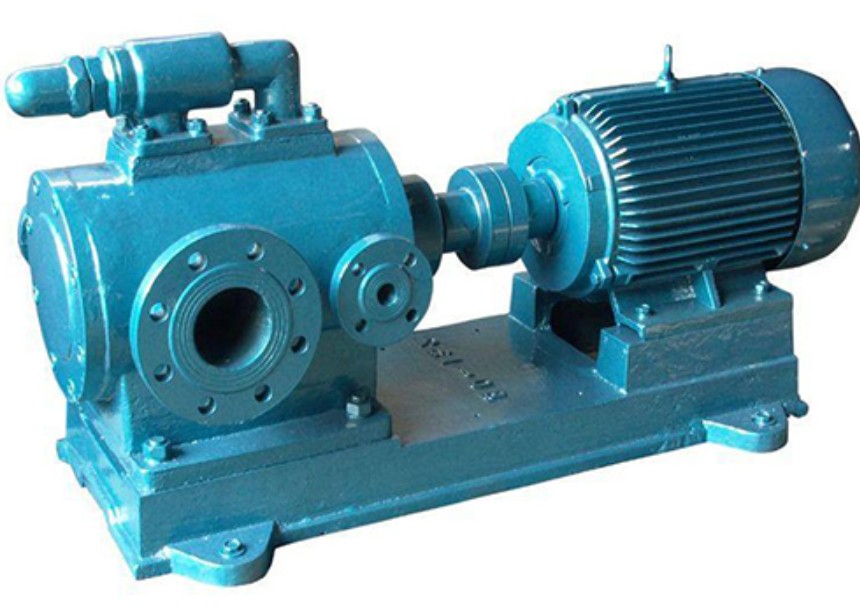

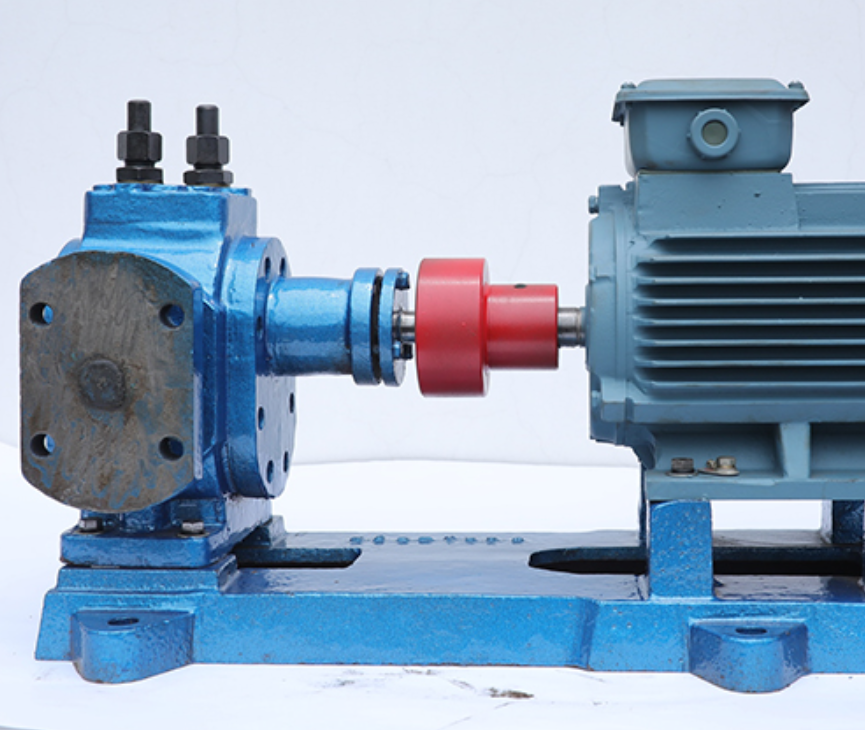

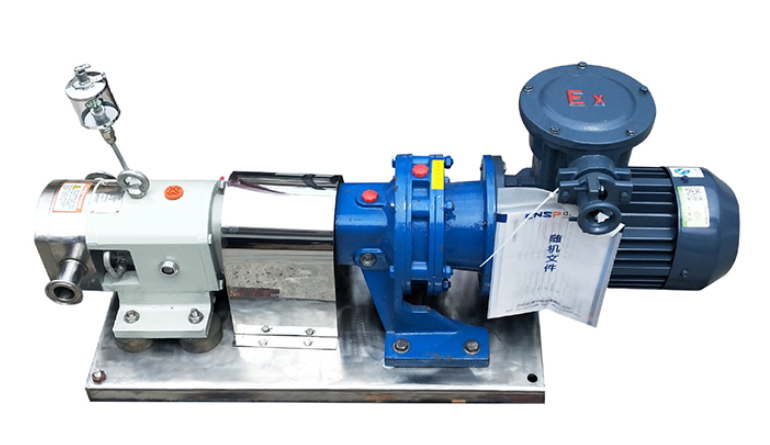

Key Selection Criteria and Material Considerations

Selecting the optimal gear pump for a high-viscosity application requires careful evaluation of several key factors beyond just flow rate and pressure. The viscosity range of the fluid is paramount, as it influences the required power, speed, and internal clearances of the pump. For extremely viscous materials, external bearing designs are often necessary to handle the heavy loads. The pump's construction materials must be compatible with the fluid to ensure longevity. Cast iron is common for non-corrosive oils, while stainless steel (e.g., 304 or 316) is essential for corrosive chemicals, food-grade applications, or when cleanliness is a priority. The choice of gear type is also critical. External gear pumps are versatile and widely used. However, for applications demanding gentle handling or dealing with liquids containing soft solids, lobe gear pumps or internal gear pumps are preferred as they offer larger flow paths and are less prone to causing damage. Finally, consideration must be given to seal options. Mechanical seals, chosen based on the fluid and temperature, are standard, but for hazardous or leak-sensitive fluids, magnetically coupled (sealless) gear pumps provide the ultimate containment and safety, preventing leaks entirely.

In summary, gear pumps are uniquely suited for handling high-viscosity liquids due to their positive displacement principle, which guarantees a steady, pulseless flow independent of pressure changes. Their advantages in self-priming, robustness, and ability to handle thick fluids efficiently make them an indispensable solution across industries from chemical processing to food and beverage. A successful application hinges on a meticulous selection process that accounts for fluid properties, material compatibility, and operational requirements, ensuring reliable performance and long service life in challenging pumping tasks.