Inside Takada Pump Industry Factory

Inside Takada Pump Industry Factory

Precision Manufacturing: From Raw Material to Pump Casing

The manufacturing journey at Takada Pump Industry begins with the arrival of high-grade raw materials, primarily ductile iron and stainless steel castings, which undergo rigorous incoming quality inspection. The production of key components like pump casings and impellers is centered on computer numerical control (CNC) machining centers. These state-of-the-art machines translate digital designs into physical parts with micron-level precision, ensuring that every volute casing and impeller vane conforms exactly to the hydraulic design specifications. This stage is critical for achieving high pump efficiency, as the internal clearances and surface finish of these components directly impact performance and longevity. The workshop is organized using lean manufacturing principles, with a clear workflow that moves from rough machining to finishing operations. Each machined part is meticulously cleaned and inspected for dimensional accuracy before proceeding to the assembly line. This disciplined approach to precision manufacturing forms the foundation for building reliable and high-performance pumps, guaranteeing that each unit meets the stringent tolerances required for optimal operation in the field.

The Assembly Line: Where Quality Components Become a Reliable Pump

The heart of the factory is the meticulously organized assembly line, where precision-made components are transformed into complete pumping units. The process starts with the preparation of the pump baseplate and casing. Skilled technicians, following detailed work instructions, carefully install the mechanical seal—a critical component where precision is paramount to prevent leaks. The balanced impeller is then mounted onto the precisely machined pump shaft, and the entire rotor assembly is dynamically balanced to minimize vibration and ensure smooth, quiet operation. The assembly of the bearing housing is a critical step, using high-quality lubricants and precisely torqued fasteners to guarantee long service life. For critical pumps, this stage may include a partial test to verify seal integrity. Throughout the process, there is a strong emphasis on cleanliness and order to prevent contamination of internal components. Each station is equipped with the necessary tools and calibrated equipment, and technicians perform checks at multiple points, documenting key data like torque values and clearances. This structured assembly process ensures that every pump leaving the line is built to the same high standard of quality and reliability.

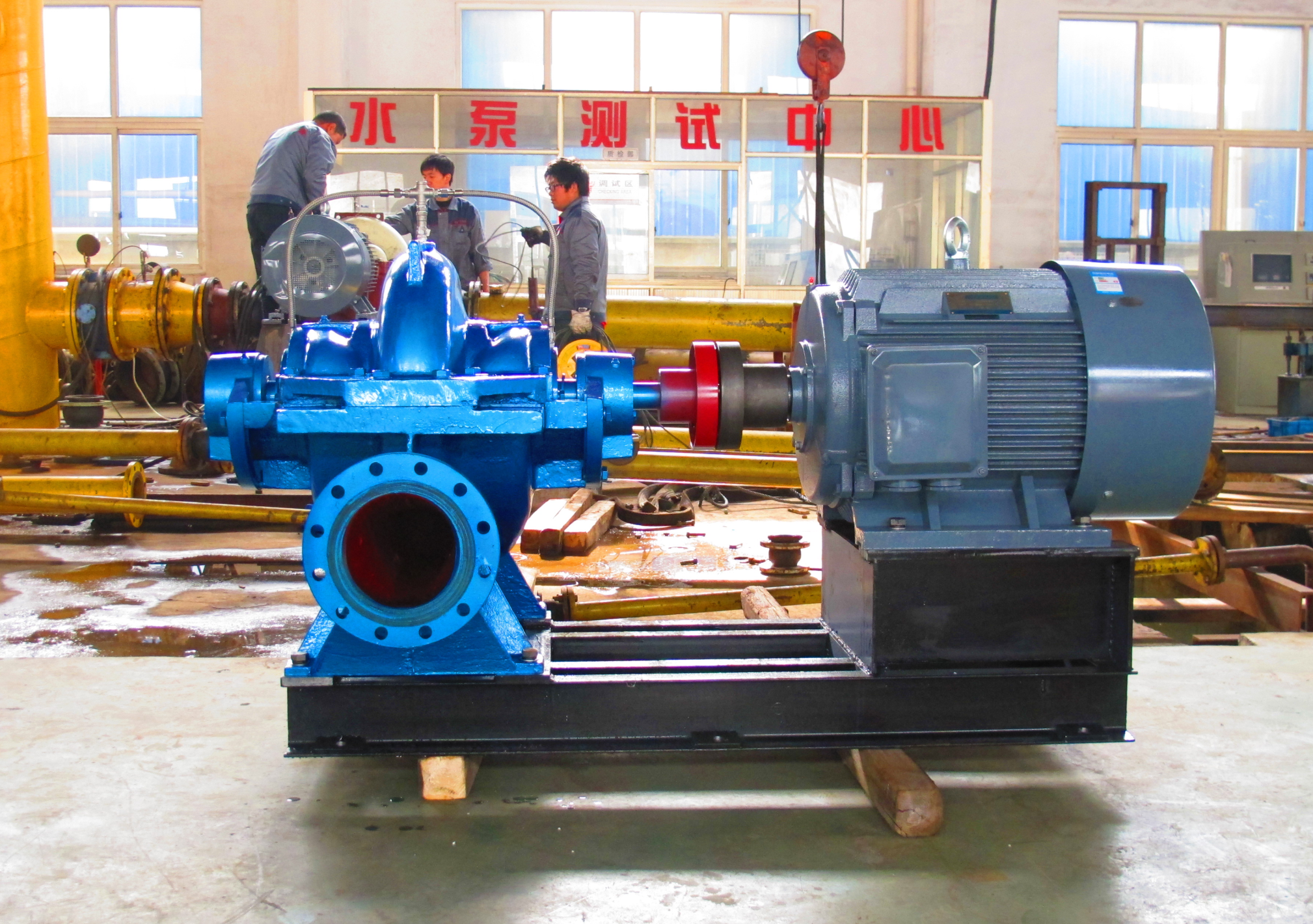

Rigorous Testing and Quality Assurance: The Final Gateway

Before any pump can be approved for shipment, it must pass a series of rigorous tests in the dedicated quality assurance center, which serves as the final gateway. The most critical of these is the hydrostatic performance test. Each pump is connected to a closed-loop test bed where its performance is measured against international standards such as ISO 9906. Key parameters like flow rate, head (pressure), input power, and efficiency are accurately recorded and plotted on a performance curve. The pump must operate smoothly at its best efficiency point (BEP) and across its entire operating range, with no abnormal noise or vibration. Additionally, every pump undergoes a hydrostatic pressure test, where the casing is subjected to a pressure significantly higher than its maximum working pressure to verify there are no leaks or structural weaknesses. For specialized pumps like fire fighting pumps, the test criteria are even more stringent, often requiring verification of performance under 150% of rated flow conditions as per NFPA 20 standards. Only after passing all these tests does the pump receive its final certification and is prepared for packaging and delivery, ensuring customers receive a product that is proven and reliable.

A tour inside the Takada Pump Industry factory reveals a world where advanced technology, skilled craftsmanship, and an unwavering commitment to quality converge. From the precision of CNC machining to the disciplined assembly process and the rigorous final testing, every step is meticulously controlled and documented. This end-to-end control over the manufacturing process is what allows Takada to consistently deliver pumps that are not just products, but reliable partners in water management for customers worldwide, ensuring performance, durability, and peace of mind.