Precision Solutions for Challenging Industrial Applications

Precision Solutions for Challenging Industrial Applications

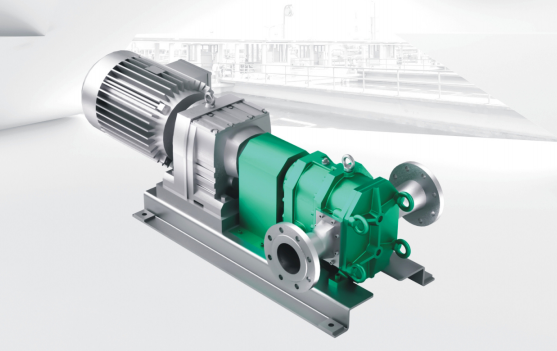

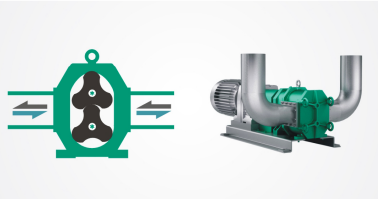

Rotary lobe pumps (also known as rotary lobe pumps) stand as versatile workhorses in fluid transfer systems, engineered to handle materials that challenge conventional pumps. GAOTIAN’s advanced lobe pump technology combines robust mechanical design with precision engineering to deliver unmatched performance across diverse industries. Here’s why they’re the preferred choice for demanding applications worldwide:

I. Core Industries & Applications

Oil & Petrochemicals

Media: Heavy crude oil, bitumen, sludge, lubricants, and polymer solutions.

Why GAOTIAN: High-viscosity handling (up to 1,000,000 cP), self-priming capability (9m vertical/100m horizontal suction), and resistance to abrasive particles. Reduces energy costs by 30% compared to screw pumps while tolerating dry-run conditions for emergency operations

Food & Beverage

Media: Chocolate, dairy (yogurt, cream), fruit pastes, sauces, and viscous additives.

Why GAOTIAN: Sanitary stainless steel construction (FDA-compliant), low-shear rotor design preserving product integrity, and CIP/SIP compatibility. Gentle handling prevents emulsion breakdown in sensitive products like custards or dressings

Chemical Processing

Media: Solvents, acids, alkalis, resins, and adhesives.

Why GAOTIAN: Corrosion-resistant materials (SS316L, Hastellay), leak-free mechanical seals, and zero-contamination design. Ideal for dosing volatile solvents or transferring reactive polymers

Wastewater & Environmental

Media: Sludge, grit-laden fluids, chemical coagulants, and fertilizer slurries.

Why GAOTIAN: Non-clogging operation passes solids up to 80mm (e.g., rags, stones), while wear-resistant rotors maintain flow rates under high-solids loading. Critical for municipal sludge dewatering and chemical dosing systems

Pharma & Cosmetics

Media: Creams, ointments, toothpaste, shampoo, and high-purity buffers.

Why GAOTIAN: Smooth internal surfaces eliminate dead zones; EHEDG-certified designs ensure cleanability. Maintains sterility in API transfer and lotion filling line

II. Engineering Advantages Driving Adoption

Uncompromising Reliability:

GAOTIAN’s patented nano-composite rubber rotors withstand 60+ minutes of dry running – critical for fail-safe operations. Combined with hardened timing gears, pumps achieve 25,000+ hour service intervalsProcess Flexibility:

Bidirectional flow capability allows reversible pumping without re-piping. Linear flow-to-RPM correlation enables precise metering (±1% accuracy), while viscosity independence supports fluctuating process conditionsEnergy Efficiency:

Low-speed operation (20–400 RPM) reduces turbulence and shear, cutting power consumption by 30–50% versus centrifugal or progressive cavity pumps. ROI typically achieved in 3–4 monthsMinimal Maintenance:

Front-access design enables seal/rotor replacement in <30 minutes without disconnecting pipes. Only 3 moving parts reduce failure risks

III. Technical Specifications Summary

| Parameter | Capability |

|---|---|

| Viscosity Range | 1 cP – 1,000,000 cP |

| Max Pressure | 15 bar (217 psi) |

| Temperature Range | -20°C to +250°C (with jacketed options) |

| Solids Handling | Up to 80mm diameter |

| Connections | DIN, SMS, Tri-Clamp, ANSI flanges |

Why Choose US?

Gaotian pumps integrate German-engineered kinematics with Japanese manufacturing precision, delivering solutions where others fail. Our pumps feature:

Gas-Liquid Adaptive Technology: Eliminates vapor lock during high-suction applications

Triple-Seal Protection: Teflon/ceramic seals with flushing ports for hazardous fluids

Smart Monitoring: IoT-enabled vibration/temperature sensors for predictive maintenance.