Selecting the Right Gaotian Pump Material for Corrosive Environments

Selecting the Right Gaotian Pump Material for Corrosive Environments

Choosing the correct pump material is not merely a specification point; it is a critical decision that determines the longevity, reliability, and total cost of ownership of pumping equipment in corrosive environments. Shanghai Gaotian Pump Manufacturing Co., Ltd. understands that factors such as the chemical composition, concentration, temperature of the fluid, and the presence of abrasive particles must be meticulously evaluated. An incorrect material choice can lead to rapid deterioration, frequent downtime, and costly repairs, jeopardizing entire operations. Gaotian's expertise lies in guiding customers through this selection process, ensuring that the pump not only functions but thrives in challenging conditions, thereby safeguarding their investment and operational continuity. The company's diverse material portfolio is engineered to meet a wide spectrum of corrosive challenges, from aggressive chemicals to saline seawater.

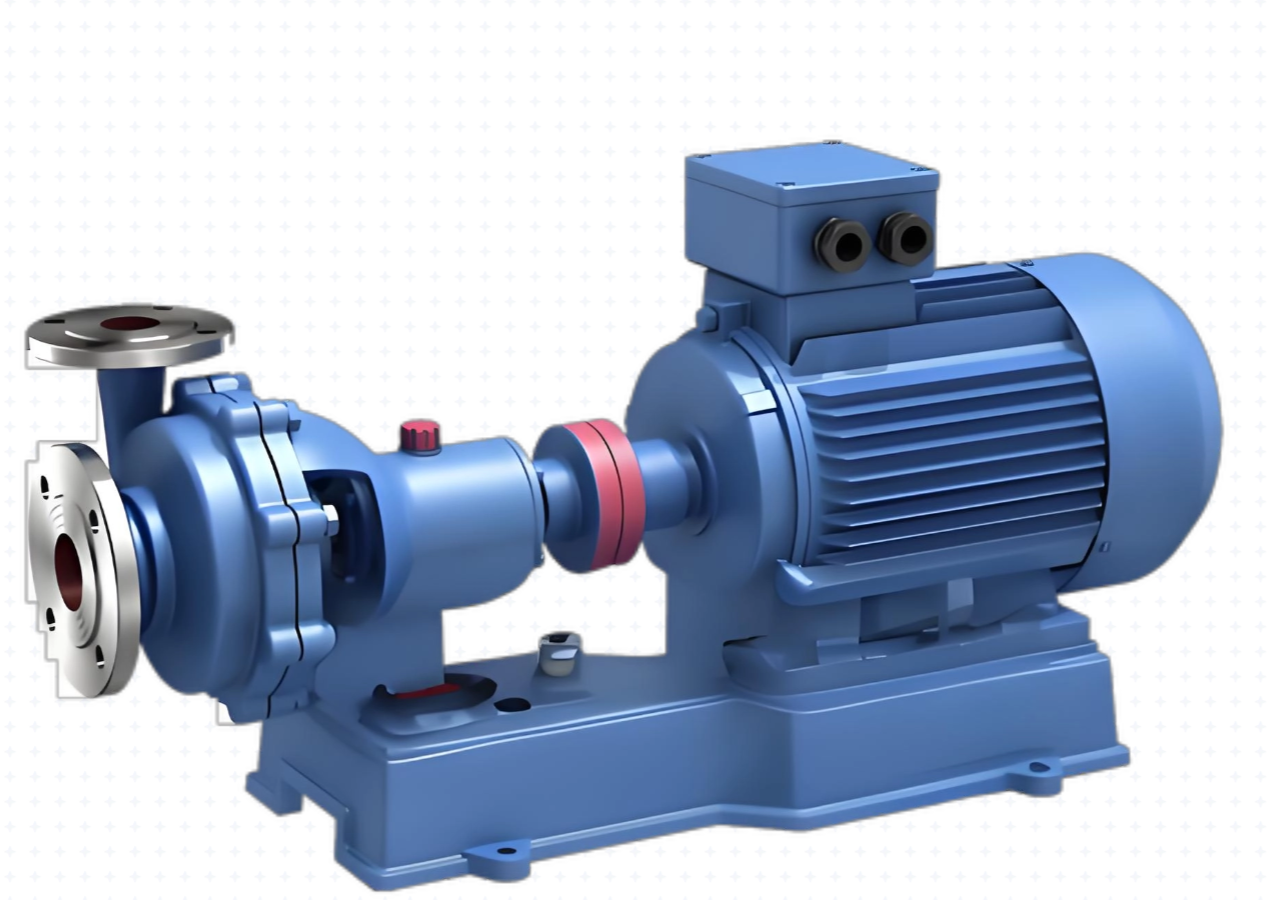

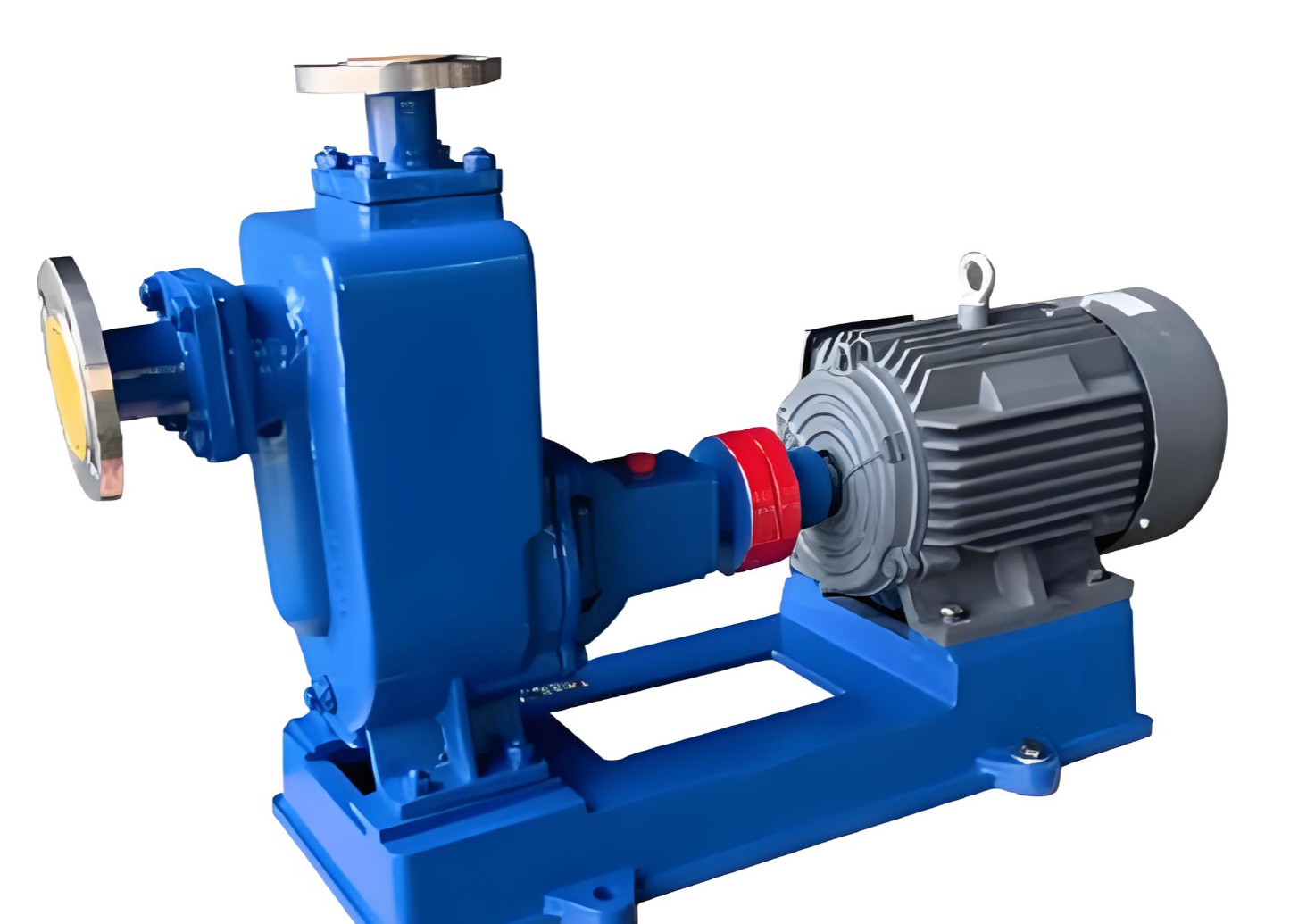

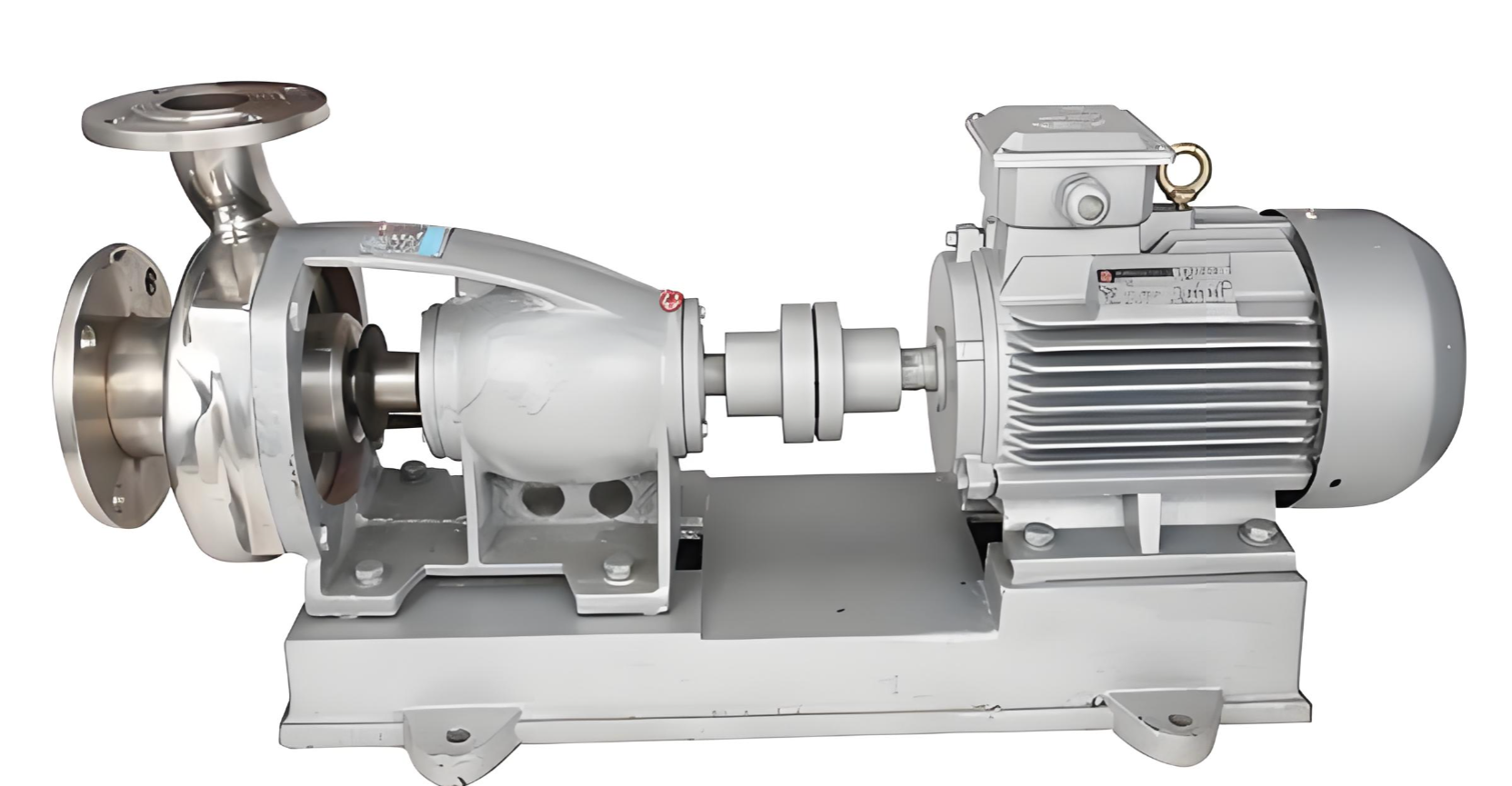

Stainless Steel: The Premier Choice for Versatile Corrosion Resistance

For a broad range of moderately corrosive applications, Gaotian's stainless steel pumps, particularly those crafted from SS304 and SS316/316L, offer an exceptional balance of performance and cost-effectiveness. SS304 provides excellent resistance to a variety of corrosives, including many organic and inorganic chemicals, making it suitable for food processing, pharmaceutical applications, and general water services. However, for environments involving chlorides, such as seawater, brackish water, or specific chemical processes, SS316 is the superior choice. The addition of molybdenum in SS316 significantly enhances its resistance to pitting and crevice corrosion. Gaotian utilizes high-grade stainless steel in critical components like impellers, casings, and shafts to ensure structural integrity and long service life, making these pumps a robust and reliable solution for demanding industrial and municipal tasks.

Specialized Alloys and Coatings for Highly Aggressive Media

When confronting highly aggressive chemicals, extreme temperatures, or combinations of corrosion and abrasion, standard stainless steels may reach their limits. For these severe service conditions, Gaotian offers pumps constructed from advanced materials such as Duplex Stainless Steel and super alloys like Alloy 20. Duplex stainless steels provide enhanced strength and superior resistance to stress corrosion cracking, ideal for high-pressure applications with chloride presence. Alloy 20 pumps excel in handling sulfuric acid and other highly corrosive media common in the chemical industry. Furthermore, Gaotian employs specialized protective coatings and linings, such as rubber or epoxy, for specific applications. These coatings create a barrier between the metal substrate and the corrosive fluid, offering a cost-effective solution for extending pump life in environments like flue gas desulfurization or abrasive slurry transfer.

In conclusion, navigating the complexities of corrosive environments demands a strategic partnership with a knowledgeable pump supplier. Shanghai Gaotian Pump Manufacturing Co., Ltd. distinguishes itself by providing not just high-quality pumps, but also the expert guidance necessary to select the optimal material for each unique application. By carefully matching their extensive material portfolio—from robust cast iron and versatile stainless steels to specialized alloys and coatings—to the specific chemical and operational challenges, Gaotian ensures maximum pump performance, minimized lifecycle costs, and unwavering operational security for its clients worldwide. The right material choice is the cornerstone of pumping system reliability in corrosive duties.