Stainless Steel Chemical Pumps: Corrosion Resistance Explained

Stainless Steel Chemical Pumps: Corrosion Resistance Explained

The Science of Stainless Steel: Chromium and the Passive Layer

The exceptional corrosion resistance of stainless steel chemical pumps begins with a fundamental metallurgical principle: the formation of a passive layer. Stainless steel alloys contain a minimum of 10.5% chromium by mass. When exposed to oxygen, either in air or water, this chromium reacts to form a thin, inert, and ultra-adherent chromium oxide (Cr₂O₃) film on the surface of the metal. This passive layer is self-healing; if the surface is scratched or damaged, the chromium in the underlying steel immediately reacts with ambient oxygen to reform the protective layer, preventing the initiation of rust. The effectiveness of this barrier is what differentiates stainless steel from ordinary carbon steel, which lacks sufficient chromium and thus corrodes readily. The quality and stability of this passive layer are enhanced by other alloying elements. For instance, Molybdenum (Mo) is added to grades like 316 stainless steel to significantly improve resistance to pitting and crevice corrosion, particularly in chloride-rich environments commonly found in chemical processing. Understanding this self-repairing mechanism is crucial for selecting a pump that will maintain its integrity against aggressive media.

Selecting the Right Grade: 304 vs. 316 vs. Duplex Stainless Steels

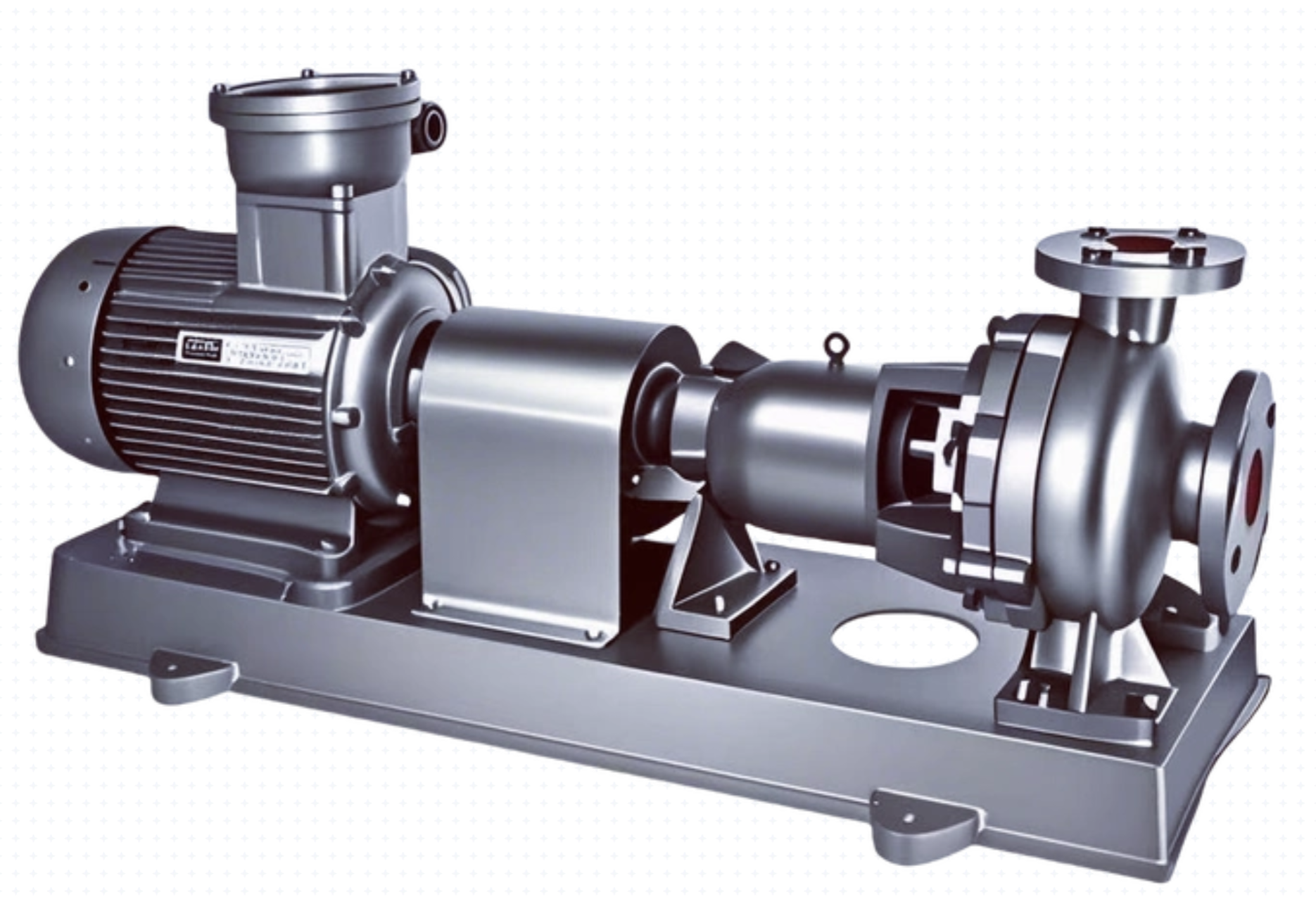

Not all stainless steels are created equal, and selecting the appropriate grade is paramount for ensuring pump longevity in specific chemical applications. The most common grades for chemical pumps are 304 (AISI 304) and 316 (AISI 316). 304 Stainless Steel offers excellent general corrosion resistance against a wide range of organic chemicals, acids like nitric acid, and food products. It is a cost-effective choice for less aggressive environments. However, 316 Stainless Steel is superior for chemical duty due to the addition of 2-3% Molybdenum. This addition drastically increases resistance to chlorides, sulfuric acid, and bromides, making it the standard for handling seawater, saline solutions, and many industrial process chemicals. For highly corrosive and demanding applications, such as those involving high chloride concentrations, extreme temperatures, or acidic conditions, Duplex Stainless Steels (e.g., 2205) are often specified. Duplex steels have a mixed microstructure that provides approximately twice the yield strength of 304 or 316 and superior resistance to stress corrosion cracking. The choice of grade is a direct trade-off between initial cost and the total cost of ownership, factoring in maintenance, downtime, and service life.

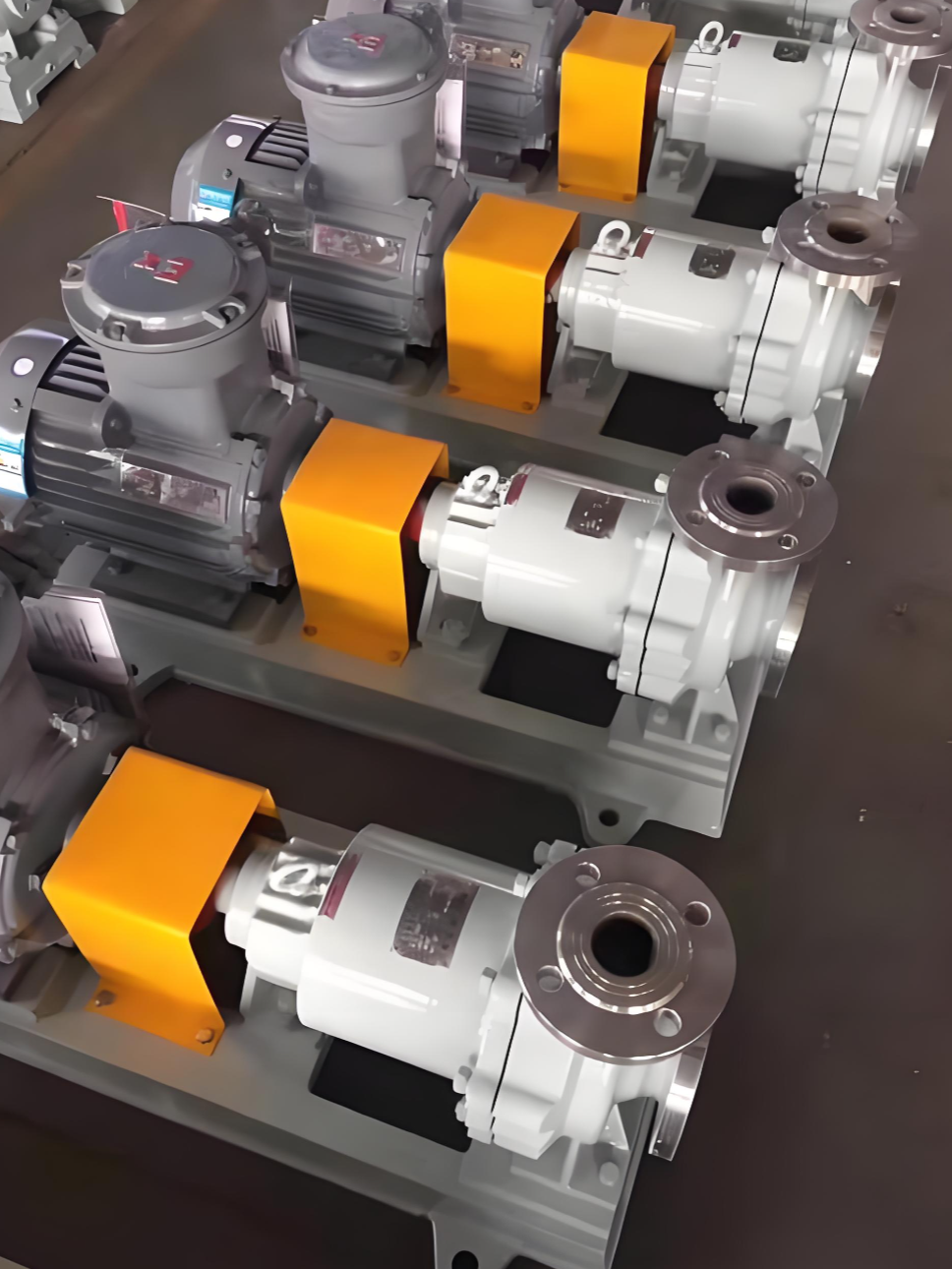

Application-Specific Corrosion Challenges and Pump Design

Beyond the base material grade, the complete design of the chemical pump must be engineered to combat specific types of corrosion encountered in practice. Uniform Attack is a general surface corrosion, guarded against by the passive layer. More insidious forms include Pitting Corrosion, localized attacks that can perforate metal, and Crevice Corrosion, which occurs in stagnant areas like gaskets or bolt threads. Pump manufacturers address these by ensuring polished surface finishes to minimize adhesion sites and designing without stagnant areas. Galvanic Corrosion can occur when dissimilar metals are in contact in an electrolyte (e.g., pump fluid). This is mitigated by using compatible materials or insulating components. Stress Corrosion Cracking (SCC) is a risk where tensile stress and a corrosive environment (especially chlorides) coexist. This is managed through proper material selection (e.g., Duplex steel), heat treatment to relieve internal stresses from casting, and robust mechanical design. Finally, the corrosion resistance must extend to all wetted parts—the impeller, shaft, seal chamber, and casing—ensuring a uniformly resistant system. The mechanical seal, a critical component, must also be selected with materials (like silicon carbide or ceramic) that complement the corrosion resistance of the pump itself.

In conclusion, the corrosion resistance of stainless steel chemical pumps is not a single property but a system engineered from the molecular level up. It hinges on the self-healing chromium oxide layer, is enhanced by strategic alloying like molybdenum in 316 steel, and is realized through meticulous grade selection and pump design tailored to defeat specific corrosive challenges. By understanding the science behind the material and the application's demands, engineers can specify pumps that deliver maximum service life, reliability, and safety in harsh chemical processing environments, ultimately protecting both the equipment and the process integrity.