The Rigorous Testing Process Every Gaotian Pump Undergoes

The Rigorous Testing Process Every Gaotian Pump Undergoes

Material Inspection and Component Verification

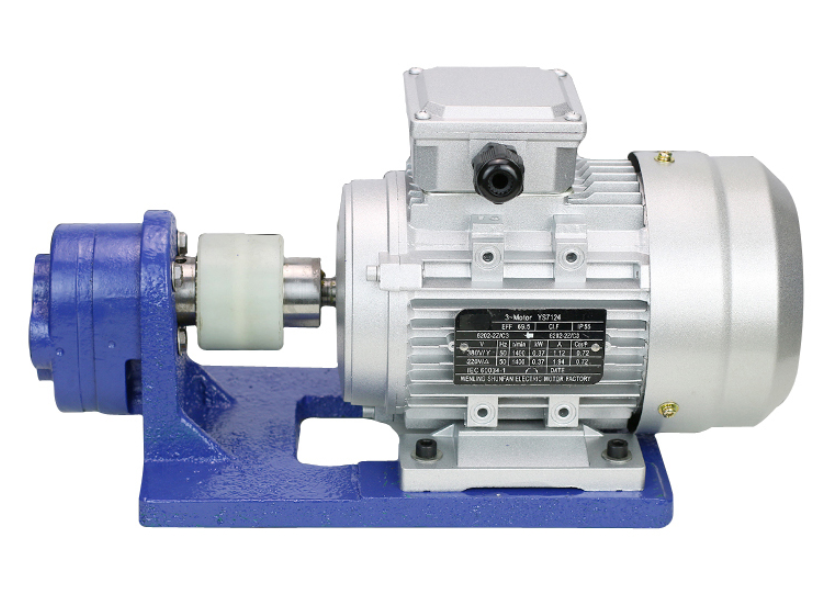

Before a single component is assembled, Gaotian's commitment to quality begins with a meticulous verification of raw materials and individual parts. This first line of defense ensures that every element entering the production line meets the stringent standards required for durable pump performance. Incoming materials, such as stainless steel plates, castings, and mechanical seal components, are subjected to rigorous checks, including material certification review and visual inspection for defects. Advanced equipment, such as laser measuring tools, is employed to validate the dimensional accuracy of critical components like impellers and pump casings against precise engineering drawings. This stage is crucial for preventing potential failures caused by substandard materials or manufacturing tolerances. By establishing this foundation of quality at the component level, Gaotian guarantees that only parts with proven integrity proceed to assembly, setting the stage for building a pump that is inherently robust and reliable from the inside out. This proactive approach minimizes risks and underscores the company's dedication to excellence long before the final product is even assembled.

Comprehensive Performance and Hydraulic Testing

Once assembled, every Gaotian pump transitions to the most critical phase of its journey: comprehensive performance testing in a state-of-the-art hydraulic test rig. This phase simulates real-world operating conditions to validate the pump's performance against its design specifications. The pump is subjected to a battery of tests, including flow rate verification across a range of pressures to map its performance curve, head pressure testing to confirm it can achieve the required lift, and efficiency measurement to ensure optimal energy consumption. Gaotian's advanced computer-controlled testing systems collect vast amounts of data in real-time, allowing engineers to analyze parameters like power absorption, vibration levels, and temperature rise. This data-driven approach ensures that each pump operates smoothly, efficiently, and within its designated envelope before it leaves the factory. Any deviation from the expected performance is immediately identified and rectified. This rigorous validation process is a testament to Gaotian's promise that every pump delivered to a customer is not just a mechanical device, but a performance-guaranteed solution ready for demanding industrial, commercial, or municipal applications.

Durability, Safety, and Final Quality Assurance

The final stage of Gaotian's testing protocol focuses on endurance, safety, and a meticulous final inspection to guarantee long-term reliability. Pumps may undergo extended run-in tests under load to simulate continuous operation, ensuring that bearings, seals, and mechanical components stabilize correctly and perform flawlessly. Safety tests, such as checks for pressure containment and grounding continuity, are conducted to protect both the equipment and the operators. For specialized pumps, such as those designed for harsh environments, additional tests like seal integrity verification under extreme conditions might be performed. Finally, a thorough visual and functional inspection is carried out. Every bolt is checked for proper torque, paintwork is inspected for uniformity and durability, and nameplates are verified for accuracy. Only after successfully passing every single test in this multi-layered, rigorous quality gate is a pump deemed worthy of bearing the Gaotian name. It is then carefully prepared for packaging and shipping, backed by the confidence that it will deliver years of dependable service, thereby upholding the company's reputation and its ISO 9001 quality management system certification.

In conclusion, the journey of every Gaotian pump through its rigorous testing protocol is a testament to an unwavering commitment to quality, performance, and customer satisfaction. From initial material checks to final performance validation, each step is designed to eliminate uncertainty and build unparalleled reliability. This disciplined process ensures that when customers choose a Gaotian pump, they are investing in more than just equipment; they are gaining a partner dedicated to delivering proven performance and enduring value for their critical operations.