The Role of Gear Pumps in Industrial Fluid Transfer

The Role of Gear Pumps in Industrial Fluid Transfer

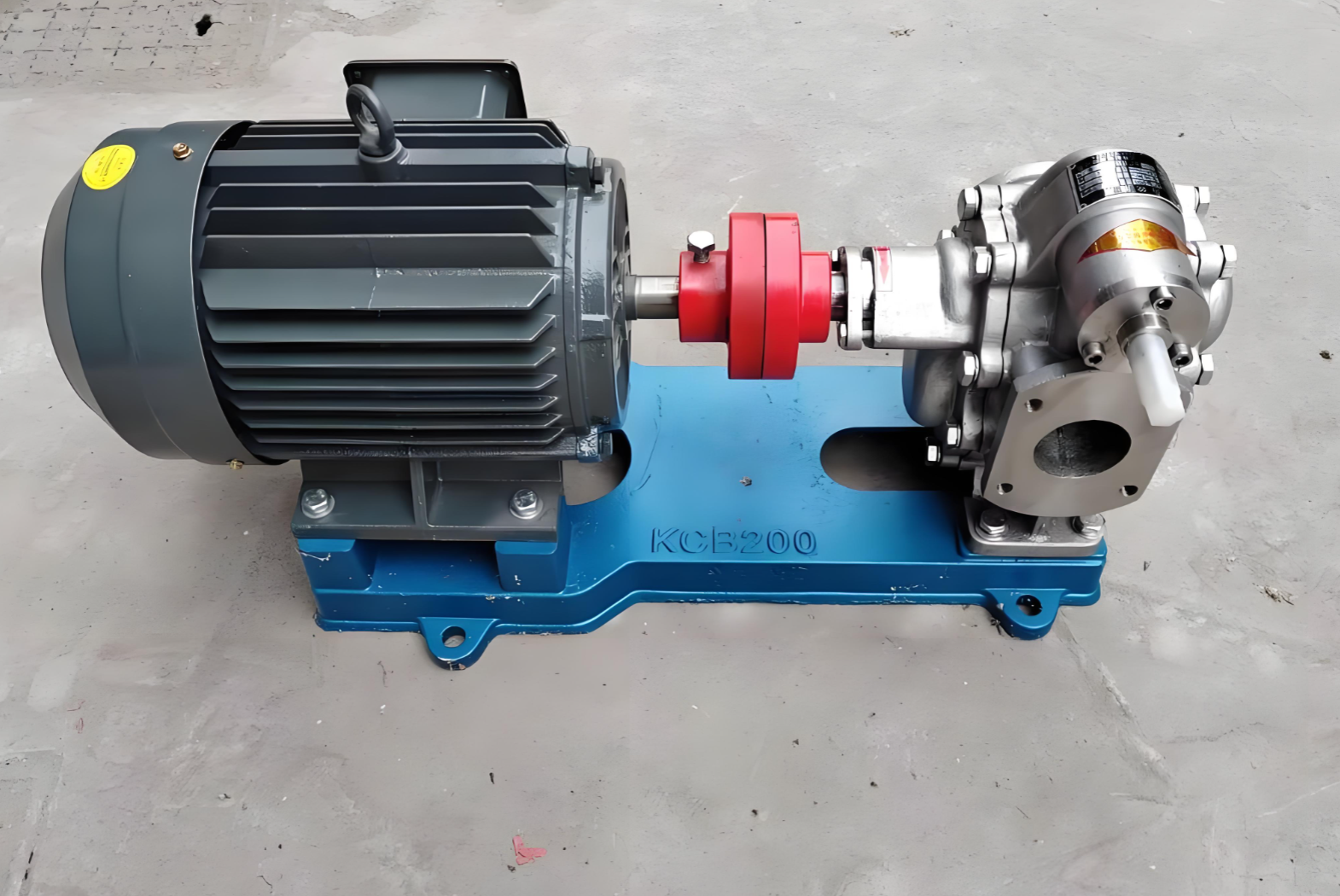

The Unmatched Principle of Positive Displacement for Consistent Flow

In the diverse portfolio of Gaotian Pump's solutions, gear pumps stand out for their unique operating principle and exceptional reliability in handling viscous fluids. Unlike centrifugal pumps that rely on imparting velocity to fluid, gear pumps operate on the positive displacement principle. This involves two precisely meshing gears—typically one driven and one idler—rotating within a tightly toleranced housing. As the gears rotate, fluid is trapped in the cavities between the gear teeth and the pump housing, carrying it from the suction side to the discharge side. The meshing of the gears at the outlet creates a positive displacement, forcing the fluid out with a smooth, non-pulsating flow that is largely independent of the discharge pressure. This fundamental characteristic makes Gaotian's gear pumps indispensable for applications requiring a consistent, precise volumetric flow rate. Whether transferring high-viscosity oils, fuels, resins, paints, or adhesives, these pumps deliver a reliable and measurable amount of fluid with every revolution, ensuring accuracy in processes such as lubrication, fuel transfer, and chemical dosing, where flow consistency is paramount for both product quality and operational safety.

Engineered for Durability and Versatility in Demanding Industries

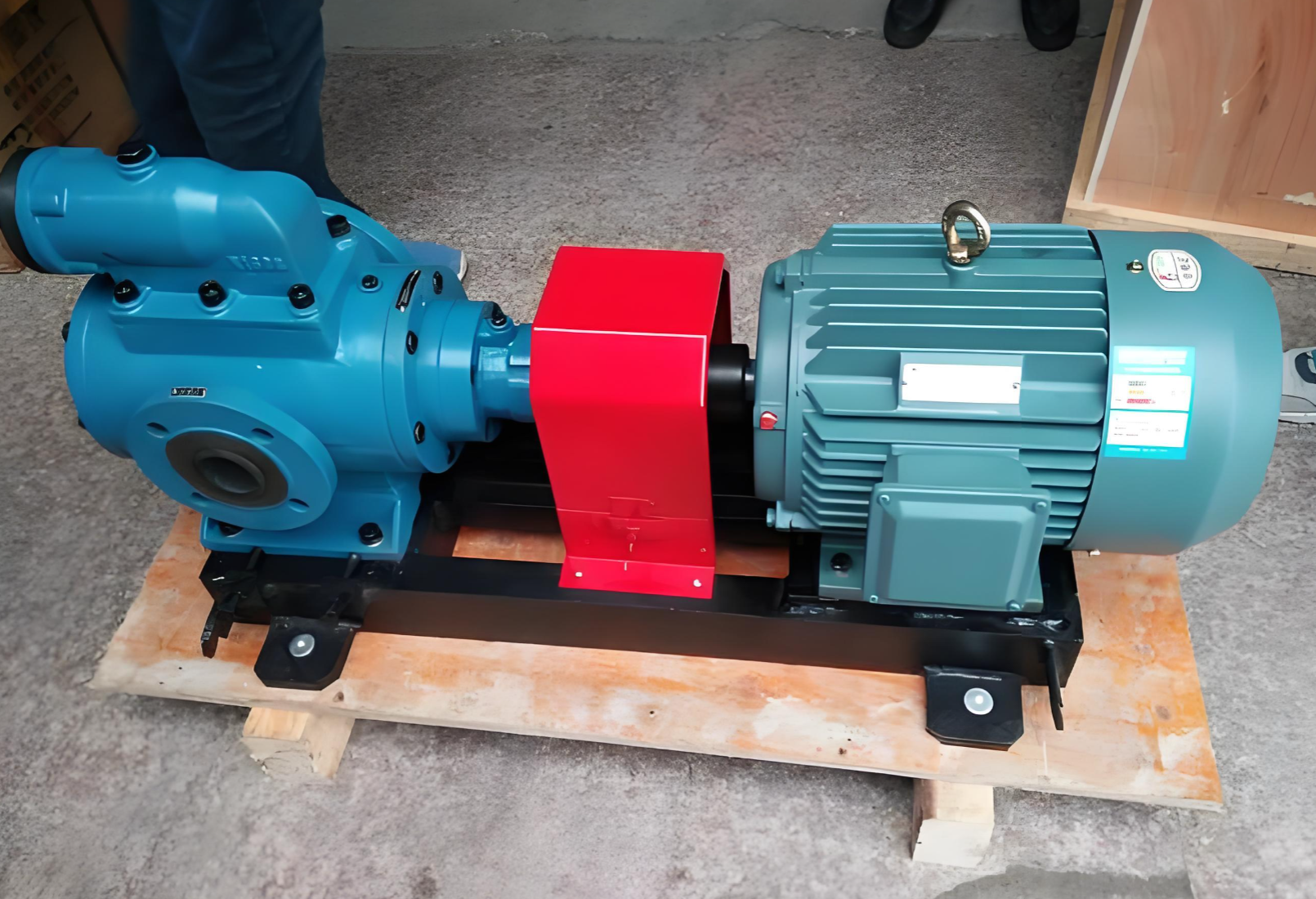

Gaotian's engineering excellence is evident in the robust construction and material selection of its gear pump range, designed to withstand the rigors of various industrial environments. The pumps are meticulously manufactured using advanced techniques and high-grade materials such as cast iron, stainless steel, and specialized alloys to suit different fluid compatibilities and abrasive challenges. For instance, when handling aggressive chemicals or solvents, Gaotian offers gear pumps with stainless steel components for enhanced corrosion resistance. The simplicity of the gear pump design contributes to its remarkable durability and ease of maintenance. With fewer complex internal parts compared to other pump types, Gaotian gear pumps are less prone to failure and can tolerate a degree of dry running better than many centrifugal pumps. This robustness, combined with their self-priming capability and ability to handle fluids with a wide range of viscosities, makes them a versatile choice across numerous sectors. From transferring lubricants in manufacturing plants and pumping diesel in agricultural settings to circulating heavy fuels in power generation and handling polymers in chemical processing, Gaotian's gear pumps provide a dependable and efficient transfer solution that keeps critical industrial processes running smoothly.

Integral to Modern Industrial Systems and Gaotian's Holistic Approach

Beyond standalone fluid transfer tasks, gear pumps play a critical role as integral components in larger, more complex systems that Gaotian helps to engineer and support. Their precise metering capability makes them ideal for use in automated lubrication systems, where exact amounts of oil or grease must be delivered to bearings and machinery at predetermined intervals. In hydraulic power units, gear pumps serve as the primary power source, generating the flow needed to drive actuators and cylinders. Gaotian's understanding of these system-level applications allows the company to offer not just a pump, but a tailored solution that includes technical support for integration and operation. Furthermore, Gaotian's commitment to quality, underscored by its ISO 9001 certification, ensures that every gear pump undergoes rigorous testing to guarantee performance and longevity. This holistic approach—combining robust product design, extensive application knowledge, and comprehensive after-sales service—positions Gaotian's gear pumps as more than just components; they are reliable partners in optimizing efficiency and productivity for businesses that depend on the precise and reliable movement of fluids.

In conclusion, gear pumps are a cornerstone of industrial fluid transfer, valued for their precise, pulse-free flow, handling capability of viscous media, and robust design. Shanghai Gaotian Pump Manufacturing Co., Ltd. leverages these inherent advantages through superior engineering, material science, and a deep understanding of diverse industrial needs. By providing reliable, durable, and application-specific gear pump solutions, Gaotian plays a vital role in ensuring the smooth and efficient operation of countless processes across manufacturing, energy, chemical, and agricultural industries worldwide.