High-pressure vertical multistage centrifugal pump

- GAOTIAN

- Shanghai

- 2000 sets

Compact Design, Space-Saving

Modular Dry-Running Mechanical Seal for Easy Maintenance

Hydraulically Optimized for High Pressure and High Efficiency

Permanent Magnet Motor with Advanced Technology for Energy Efficiency and Environmental Protection

Pump Introduction

High-pressure vertical multistage centrifugal pump is designed with customized mechanical seals and fluid components to withstand high-pressure applications of certain fluid solutions, primarily addressing the high-pressure requirements in the field of machine tool cooling.

The company utilizes cutting-edge technology to develop the MSP high-pressure submerged multistage centrifugal pump, paired with a permanent magnet motor capable of operating at 5000 RPM for extended periods, achieving a breakthrough of up to 600m pressure with a single pump.

Pump Connection Method

● Pipe thread

Pump Material

Stainless steel (AISI304, AISI316)

Duplex stainless steel (2205)

Pump Liquid Temperature

● Liquid temperature: -15°C to +70°C

Pump Operating Conditions

● Thin, clean, non-flammable, non-explosive liquids free of particles or fibers

● Ambient temperature: Not exceeding +40°C

● Altitude: Not exceeding 1000m

Motor

● Squirrel cage totally enclosed fan-cooled IEC motor, suitable for continuous operation

● Protection class: IP55

● Insulation class: F

● Standard voltage: 3x380-415V

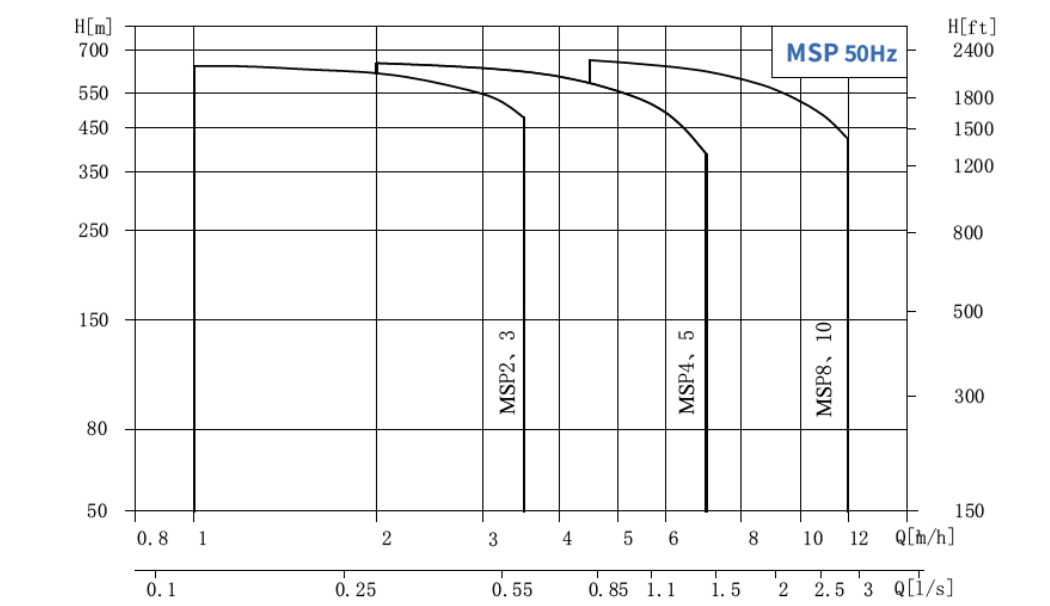

Performance Curve

● All curves are based on test values with the motor at a constant speed of 5000 RPM.

● Curve tolerance complies with ISO9906.

● Tests conducted with air-free water at 20°C and a kinematic viscosity of 1 mm²/s.

● Pump usage should refer to the performance range indicated by the bold line to prevent overheating due to low flow or motor overload due to excessive flow.

Altitude and Ambient Temperature

When the pump operates at an ambient temperature exceeding 40°C or an altitude exceeding 1000m, the motor output power (P2) decreases. Under such conditions, a higher-power motor is required.

Figure Description

A line graph is included, where the X-axis represents temperature T (°C) and the Y-axis represents P2 (%). The graph features two curves corresponding to altitudes of 1000m, 2250m, and 3500m. It illustrates the decrease in P2 percentage as temperature increases.

Model Chart

Typical Applications

Industrial Circulation Systems

・Machine tool coolant transfer

・Lubricant transfer

・Condensate water transfer

Filtration Systems

・Filtration systems

・Metal chip conveyors

Cleaning Systems

・EDM (Electrical Discharge Machining) machine cleaning

・Lathe cleaning

・Grinder cleaning

・Milling machine cleaning

・Drilling machine cleaning

・Polishing machine cleaning

・Industrial washer cleaning

・Cooling unit cleaning

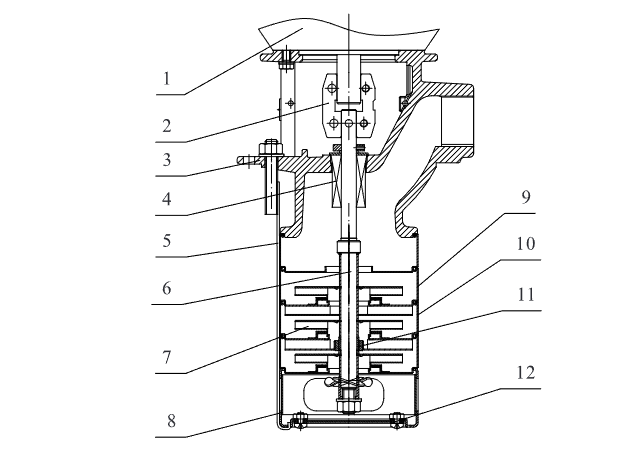

Structural and material

No. | Component | Material |

|---|---|---|

1 | Motor | / |

2 | Coupling | Ductile Iron |

3 | Bracket | Stainless Steel |

4 | Mechanical Seal | / |

5 | Tie Rod | Stainless Steel |

6 | Pump Shaft | Stainless Steel |

7 | Impeller | Stainless Steel |

8 | Inlet Body | Stainless Steel |

9 | Guide Vane | Stainless Steel |

10 | Support Guide Vane | Stainless Steel |

11 | Slide Bearing | Tungsten Carbide |

12 | Strainer | Stainless Steel |