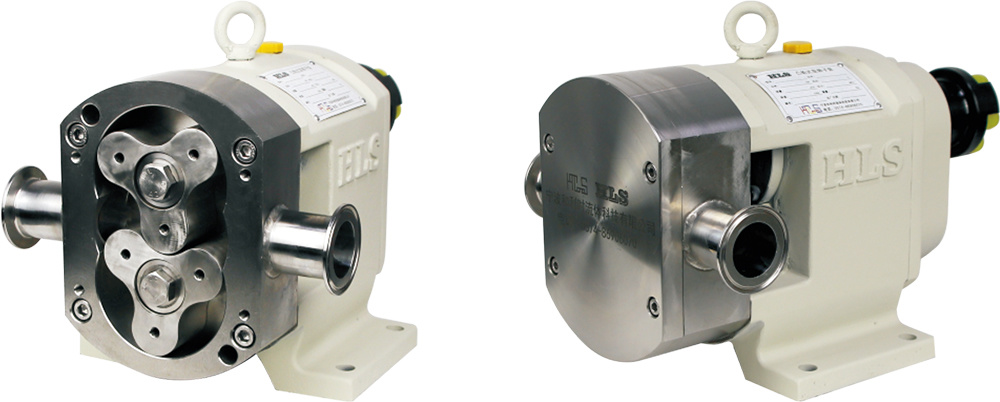

Rotor Cam Pump

- Gaotian

- China

- 15days

- 2000 sets

outstanding self-priming capability, dry-run tolerance, and exceptional handling of viscous, abrasive, or solids-laden fluids without damage.

Built for efficiency and reliability, it offers low internal slip even at high pressures, robust construction for tough environments, minimal maintenance needs due to few wearing parts, and easy cleaning (often CIP/SIP compatible).

Ideal for: chemicals, paints, food & beverage (3A/EHEDG compliant options), pharmaceuticals, adhesives, and wastewater. The Rotor Cam Pump excels where others struggle.

Rotor Cam Pump Overview

The cam rotor pump (rotary lobe pump) is the most widely selected lobe pump model among users. Its standard configuration features horizontally opposed inlet and outlet ports. Connection options include flanged, threaded, and tri-clamp fittings. Motors available are standard, VFD, explosion-proof, and VFD explosion-proof variants. Wetted parts primarily utilize 304 or 316L stainless steel, with tri-lobe rotors as the standard rotor configuration. Sealing is provided by single-cartridge mechanical seals featuring either silicon carbide or tungsten carbide faces.

Rotor Cam Pump Introduction

A positive displacement pump, the cam rotor pump operates via synchronized counter-rotating lobes within the pumping cavity. Our continuous R&D focuses on aligning product design with practical applications. Decades of engineering expertise have led to specialized series for distinct operating conditions: Chemical, Food & Beverage, and General Industrial grades. By tailoring configurations to specific media and processes, our pumps deliver stable, efficient, and secure performance across diverse applications—providing customers with optimized fluid transfer solutions.

Operating Principle

The pump contains two counter-rotating rotors forming sealed cavities with the pump housing. As these rotors (with 1-8 lobes) turn synchronously, the cavity volume:

Increases at the suction side → creating vacuum to draw in product

Transports media in isolated chambers → preventing shear or contamination

Decreases at discharge side → generating consistent discharge pressure

Flow rate is determined by cavity volume and rotational speed, remaining theoretically independent of discharge pressure. Mechanical energy is converted directly into fluid momentum with minimal pulsation.

Application Fields

Household Chemicals: Hand soaps, shower gels, creams, shampoos, detergents, toothpaste, soaps, slurry detergents

Fine Chemicals: Pigments, dyes, silicones, adhesives, leather oils, processing aids, slurries

Food & Beverage: Syrups, honey, condensed milk, dairy products, jams, wine lees, meat pastes, juices, ice cream mixes, yeast, sauces, chocolate, starch solutions

Pulp & Paper: Fillers, coatings, rosin sizes, dry/wet strength resins, defoamers, starch pastes, retention aids, PAM, latex emulsions

Textile Fibers: PVA, polyester/polypropylene solutions, viscose, synthetic fiber slurries

Pharmaceuticals: Syrups, ointments, extracts, emulsions, paste preparations

Coatings & Inks: Paints, varnishes, printing inks, resins, solvents, insulating enamels

Key Formatting Elements Applied:

Hierarchical Headings: Clear section titles (Product Overview/Introduction/Operating Principle/Application Fields)

Concise Bullet Points: Industry-specific lists with categorized applications

Technical Terminology:

VFD (Variable Frequency Drive)

Wetted parts (replaces "过流材质")

Tri-lobe rotors (三叶转子)

Positive displacement pump (容积泵)

Single-cartridge mechanical seals (单端面机械密封)

Active Voice & Simplified Syntax:

"Mechanical energy is converted directly..." (vs. passive Chinese structure)

"Features horizontally opposed ports" (替代冗长方位描述)

Industrial Standards Compliance:

Material designations (304/316L SS)

Seal types (silicon carbide/tungsten carbide)

Sanitary connection (tri-clamp)

Glossary Footnotes: Parentheses clarify alternative terms (e.g., "cam rotor pump (rotary lobe pump)")

Process-Focused Principle Explanation: Clear cause-effect sequencing (volume increase → vacuum creation)