Slurry pump

- GAOTIAN

- Shanghai

- 7-15days

- 2000 sets

Four Major Advantages of Slurry pump : Easy Operation, Corrosion and Abrasion Resistance, Economic Operation, Excellent Sealing.

Suitable for the transport of Bentonite, Calcium Carbide Slag, Lime Milk, Coal, Gypsum Slurry, and Sandy Crude Oil.

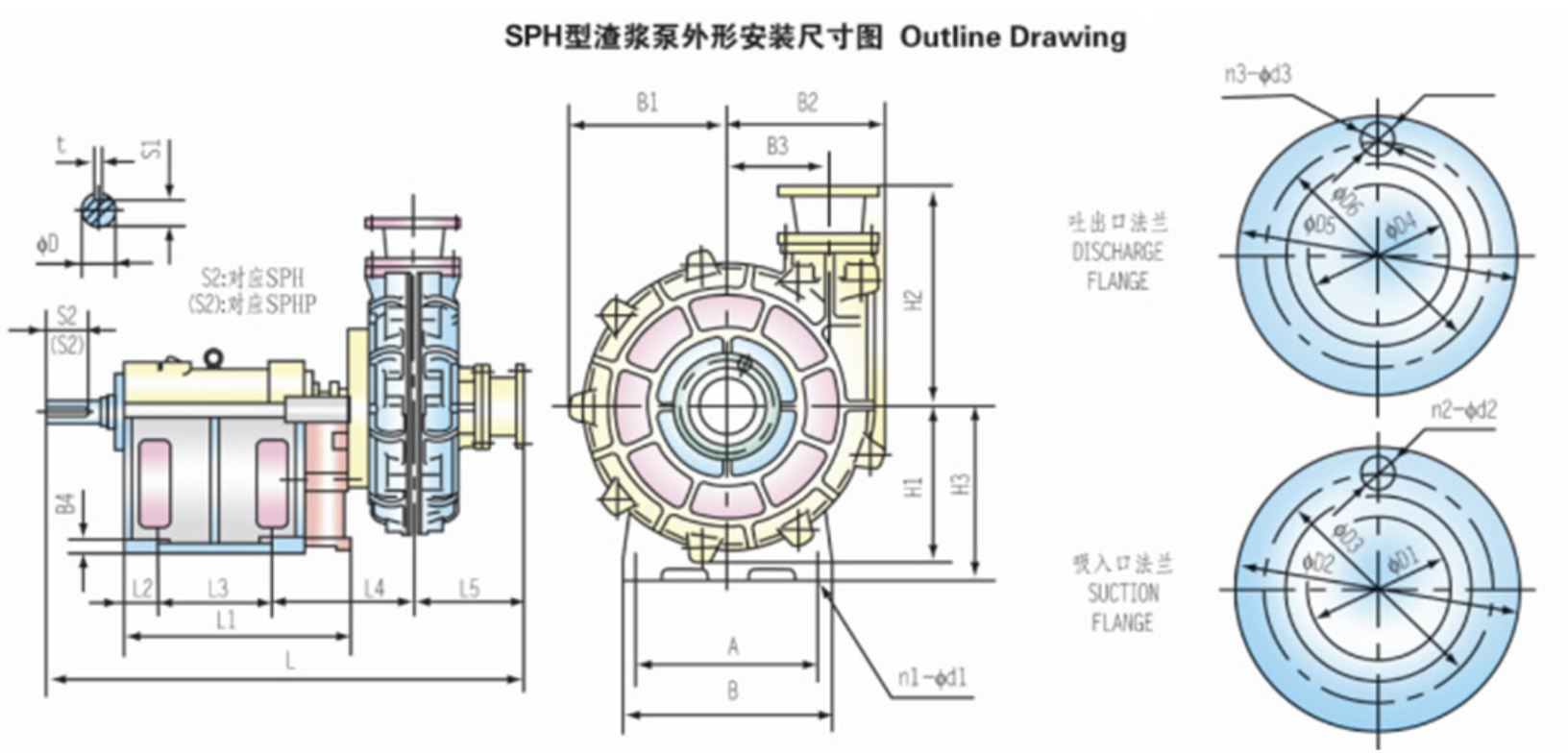

Technical Parameters:

Flow Rate Range: 20–700 m³/h

Head Range: 8–80 m

Liquid Temperature: -20–180 ℃

Slurry pump description

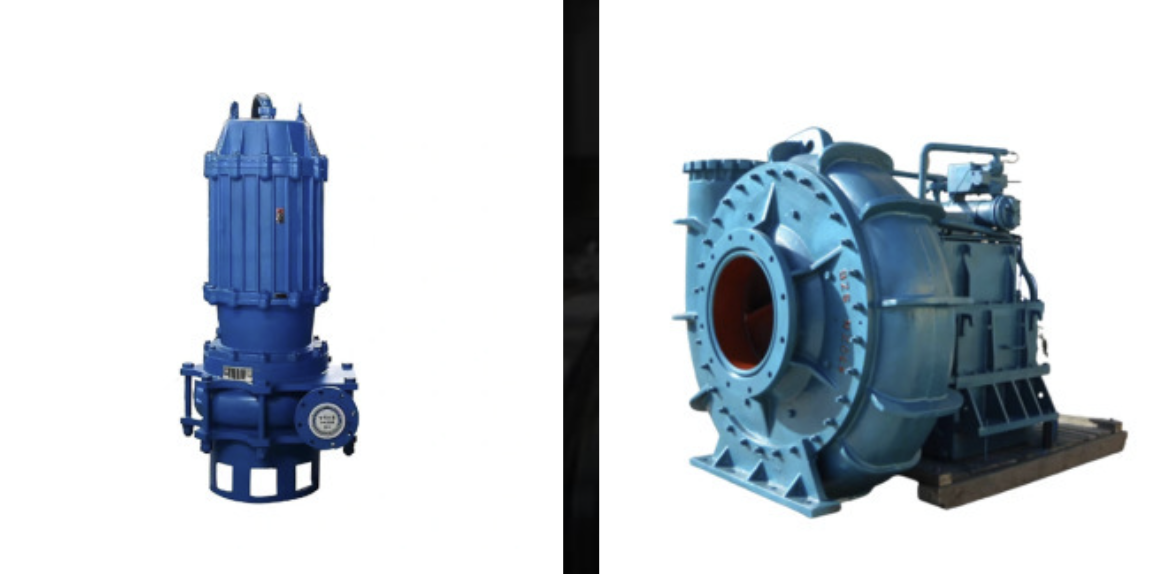

The slurry pump is a single-stage, single-suction, centrifugal slurry pump designed for our plant. The flow-passing components of this series are made of high-hardness alloy cast iron, offering high resistance to abrasion, corrosion, and impact, thereby extending the pump's service life. This pump series is classified into horizontal (SPL series) and vertical (SPL series) types based on its structure. Horizontal pumps are available in various outlet diameters including 350mm, 300mm, 250mm, 200mm, 150mm, 100mm, 80mm, 65mm, 50mm, and 40mm; for each diameter, impellers of different sizes are available to meet various head requirements. It is suitable for industries such as power, metallurgy, coal, building materials, and chemicals, primarily for conveying abrasive slurries containing solid particles. Applications include handling concentrates and tailings in mineral processing plants, ash and slag removal in power plants, transporting coal slurry and heavy media in coal washing plants, and conveying ore slurry in coastal and river mining operations. The maximum weight concentration it can handle is 45% for ash slurry and 60% for ore slurry. Drive methods include direct coupling, belt drive, hydraulic coupling, and variable frequency drive. It can also be operated in series or parallel configurations based on user requirements.

Main Technical Features:

The slurry pump series boasts the following key technical characteristics:

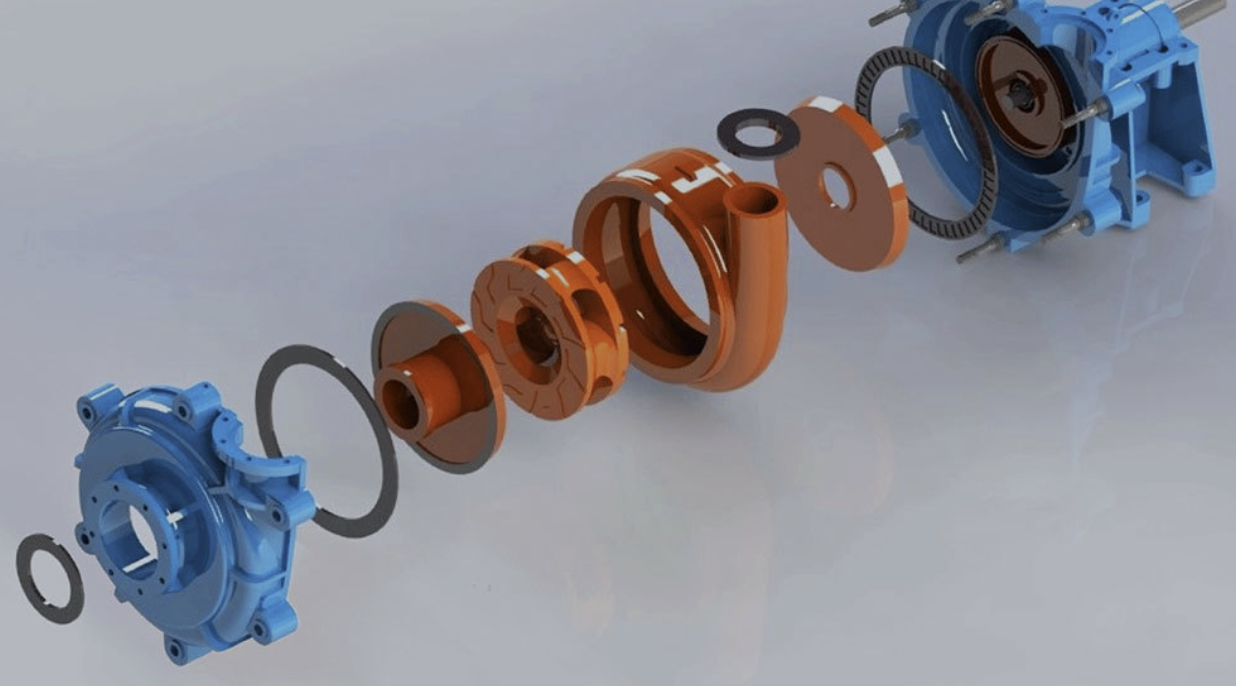

Utilizes modern CAD design methods, delivering excellent hydraulic performance, high efficiency, and low wear rates.

Features spacious flow passages for superior anti-clogging performance and exceptional cavitation resistance.

Employs a combination of auxiliary impeller, packing seal, and mechanical seal to ensure zero slurry leakage.

Incorporates reliability-focused engineering, significantly increasing the Mean Time Between Failures (MTBF).

Adopts metric bearings with oil lubrication and an optimally configured lubrication and cooling system, ensuring low-temperature operation of bearings.

Wetted parts are constructed with special materials, offering outstanding wear and corrosion resistance.

Specially treated to handle seawater ash removal and electrochemical corrosion environments involving seawater and salt spray.

Supports multi-stage series operation within allowable pressure limits, with a maximum working pressure of 3.6 MPa.

This slurry pump series is designed with a rational structure, high efficiency, reliable operation, and ease of maintenance. It is widely suited for transporting abrasive or corrosive slurries across industrial sectors such as:

Power (e.g., ash and slag handling in thermal power plants)

Metallurgy

Mining

Coal

Building Materials

Chemical Industry

It is particularly well-adapted for ash handling in power plants.