Submerged Pump

Submerged Pump is primarily suitable for conveying corrosive, coarse particles, and high-concentration slag slurry. It is widely used in metallurgy, mining, coal, electric power, building materials, environmental protection, and other sectors .

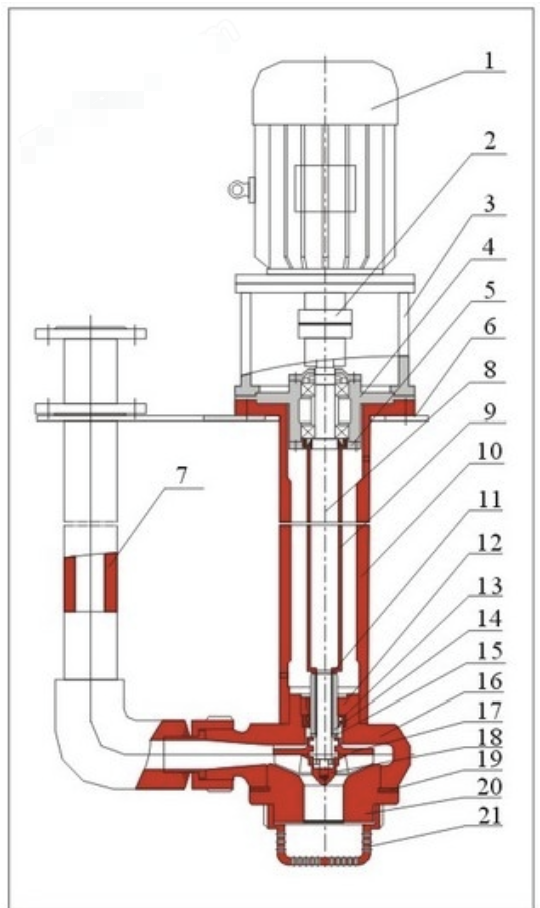

The SP type pump is a vertical centrifugal slurry pump. The pump inlet is vertically downward, and the outlet is vertically upward on the other side of the pump. The pump is mainly composed of a lower filter screen, pump body, impeller, shaft, guard plate, bracket, and other parts. The upper part of the pump is supported by a bearing; the pump is installed under the liquid without any shaft seal, and the flow-through parts are made of wear-resistant materials .

The transmission types of this pump are BD and DC, namely belt drive and direct coupling drive. The depth of immersion in the liquid can be determined according to the actual needs of users within the standard size range .

Seen from the direction of the pump suction port, it rotates counterclockwise.

The submerged slurry pump is a vertical centrifugal slurry pump that operates immersed underwater, designed for conveying abrasive, coarse-particle, and high-concentration slurries. It requires no shaft seal or seal water, and can function properly even under conditions of insufficient suction flow.

The pump's wetted parts are constructed from wear-resistant metal. Components submerged in the liquid are lined with rubber, making it suitable for handling slurries with abrasive but non-angular particles.

No. | Name | Material |

|---|---|---|

1 | Motor | Y-series B5 Motor |

2 | Coupling | HT200 |

3 | Bracket | HT200 |

4 | Bearing Seat | HT200 |

5 | Lower Side Cover | |

6 | Mounting Plate | A3 Steel |

7 | Discharge Pipe | Polypropylene + Fiberglass |

8 | Main Shaft | 45# Steel |

9 | Shaft Sleeve | Polypropylene |

10 | Connection Tube | Polypropylene or Fiberglass |

11 | Sleeve Gasket | Fluororubber |

12 | Split Ring | UHMWPE |

13 | K-type Ring | Fluororubber |

14 | Sleeve | 99% Alumina Ceramic |

15 | Impeller Gasket | Fluororubber |

16 | Pump Body | UHMWPE or Polypropylene |

17 | Impeller | UHMWPE + 1Cr18Ni9Ti |

18 | Lock Nut Assembly | A3 Steel + UHMWPE |

19 | Pump Cover Gasket | Fluororubber |

20 | Pump Cover | UHMWPE or Polypropylene |

21 | Strainer Cover | Polypropylene |

The length of the pump drive shaft or suction pipe can be customized based on the height of the slurry pool. Utilizing multiple speeds and various configuration options, the pump operates optimally under diverse conditions, ensuring a long service life, high operational efficiency, and the ability to meet the demands of numerous challenging conveying applications.

Pump Model | Flow (m³/h) | Head (m) | Speed (r/min) | Motor Power (kW) | Immersion Length (m) |

|---|---|---|---|---|---|

25-5-20 | 5 | 20 | 2900 | 1.5 | 1-2.5 |

32-10-20 | 10 | 20 | 2900 | 2.2 | - |

40-10-30 | 10 | 30 | 2900 | 4 | - |

50-20-30 | 20 | 30 | 2900 | 5.5 | - |

65-30-20 | 30 | 30 | 2900 | 7.5 | - |

65-30-50 | 30 | 50 | 2900 | 15 | - |

65-30-80 | 30 | 80 | 2900 | 22 | - |

80-50-30 | 50 | 30 | 2900 | 11 | - |

80-50-50 | 50 | 50 | 2900 | 18.5 | - |

80-40-80 | 40 | 80 | 2900 | 30 | - |

100-80-30 | 80 | 30 | 2900 | 18.5 | - |

100-80-50 | 80 | 50 | 2900 | 30 | - |

10-60-80 | 60 | 80 | 2900 | 45 | - |

125-120-30 | 120 | 40 | 2900 | 30 | - |

125-120-50 | 120 | 50 | 2900 | 45 | - |

125-120-80 | 120 | 80 | 2900 | 75 | - |

150-150-32 | 150 | 32 | 2900 | 30 | - |

150-200-25 | 200 | 25 | 2900 | 37 | - |

150-150-45 | 150 | 45 | 2900 | 45 | - |

150-150-75 | 150 | 75 | 2900 | 75 | - |

200-350-25 | 350 | 25 | 2900 | 45 | - |

Note: The immersion length for most models was not specified in your original list. Only the model "25-5-20" included this parameter. If you have the specific immersion length data for other models, please provide it for a more complete table. The pump model nomenclature (e.g., 25-5-20) is kept as provided, as it often contains specific manufacturer coding for inlet diameter, flow, head, or other design features.