WQ(D)X-S Precision-Cast Stainless Steel High-Head Sewage/Submersible Pump (Threaded Outlet)

- Gaotian

- China

- 15days

- 2000 sets

The WQX Series represents a paradigm shift in submersible pump technology, integrating aerospace-grade materials with hydrodynamic innovation to deliver uncompromising reliability in sewage, industrial effluent, and high-solids fluid transfer.

Core Technological Superiority

1. Ultra-Durable Stainless Steel Construction

Material Integrity: 304/316L stainless steel body (model-specific) provides exceptional corrosion resistance against H₂S, chlorides, and acidic effluents.

Investment Casting Process: Precision-machined surfaces (Ra ≤ 3.2μm) ensure perfect sealing geometry and hydraulic efficiency.

2. Powerplant Excellence: 100% Pure Copper Motor System

Oxygen-Free Copper Windings: Enamel-coated pure copper conductors minimize I²R losses, achieving 92% motor efficiency (IE3 standard).

Thermal Defense System: Embedded Klixon thermal protectors trigger instant shutdown at 130°C ±5°C, preventing burnout during dry-run or jam events.

Magnetic Core Optimization: Cold-rolled silicon steel laminations (0.35mm thickness) reduce eddy currents by 40% versus conventional designs.

3. Tribological Mastery: Bearing & Sealing Ecosystem

SKF-Grade Bearings: Angular contact bearings pre-lubricated with Mobil SHC 634 synthetic grease sustain 20,000+ hours at 3600 RPM.

Triple-Seal Containment:

Primary seal: Silicon carbide/tungsten carbide mechanical face seal

Secondary: HNBR lip seal with anti-clogging springs

Tertiary: Labyrinth particle exclusion system

Aging Resistance: Fluorocarbon elastomers maintain elasticity across -30°C to 180°C operating range.

Performance Engineering: Beyond Specifications

Hydrodynamic Profile

Impeller Dynamics: Vortex-type open impeller (S.G. iron/duplex SS) handles 65mm spherical solids without clogging.

Hydraulic Balance: Back-vane pressure compensation eliminates axial thrust, reducing bearing load by 70%.

Operational Intelligence

Auto-Clean Function: Reverse rotation capability clears fibrous entanglements (patent pending).

VFD Readiness: All models compatible with variable frequency drives for flow modulation ±20% of BEP.

Technical Specifications: Engineered Precision

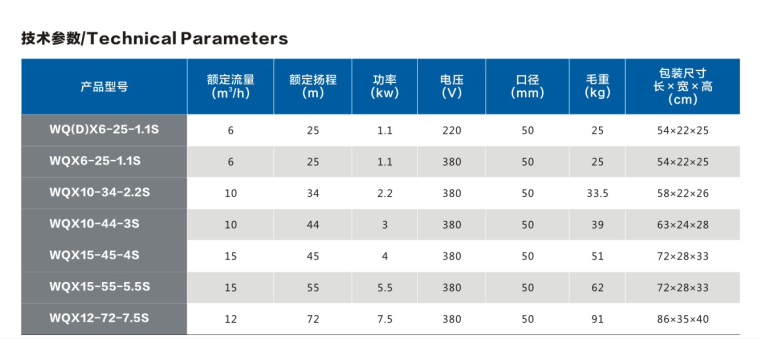

| Model | Flow (m³/h) | Head (m) | Power (kW) | Voltage | Solids Passage (mm) | Weight (kg) |

|---|---|---|---|---|---|---|

| WQ(D)X6-25-1.1S | 6 | 25 | 1.1 | 220V ∆ | 35 | 25 |

| WQX10-44-3S | 10 | 44 | 3.0 | 380V Y | 50 | 39 |

| WQX15-55-5.5S | 15 | 55 | 5.5 | 380V Y | 65 | 62 |

| WQX12-72-7.5S | 12 | 72 | 7.5 | 380V Y | 65 | 91 |

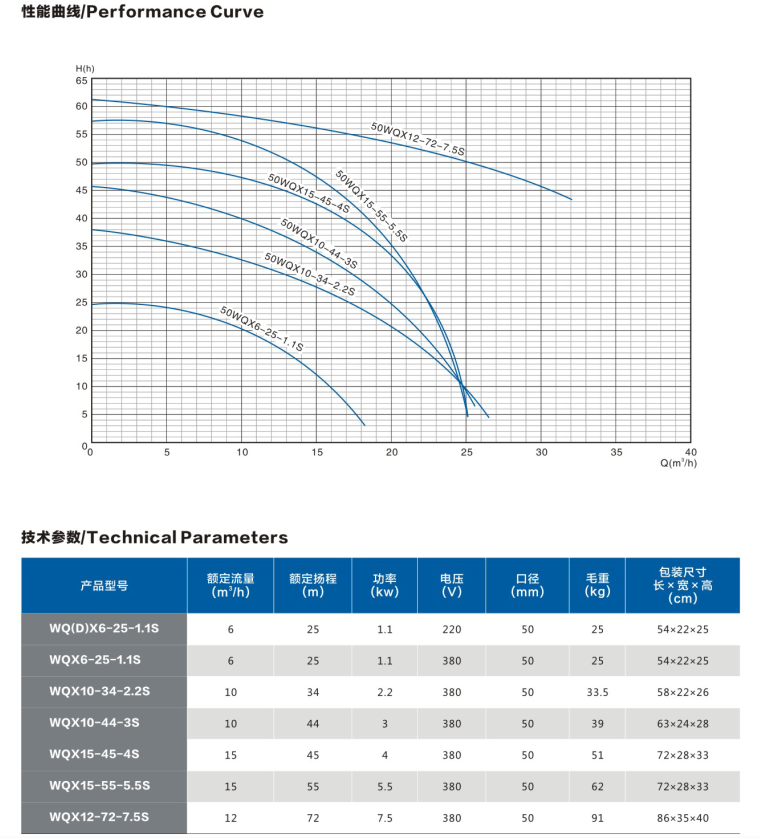

Performance curves confirm stable operation at 110% of BEP without cavitation risk.

Application-Specific Advantages

Municipal: Continuous operation in lift stations with 7% solids concentration

Industrial: Chemical-resistant variants for pH 2-14 environments

Mining: Capable of handling slurries with SG ≤ 1.3

Flood Control: Dry-pit capable models available (IP68 rating)

Lifecycle Value Proposition

MTBF: 32,000 hours (ISO 1940 balance grade G2.5)

Maintenance Interval: 2-year oil replenishment cycle

Sustainability: 98% recyclable materials, RoHS compliant